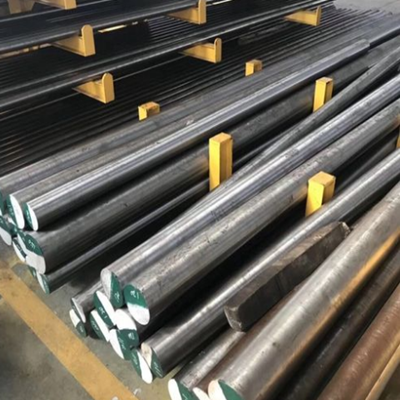

50Mn2 Alloy Steel

- GB/T 3077

- China

- Stock

- 50Mn2

50Mn2 alloy steel In the quenched and tempered state, 50Mn2 alloy steel can produce parts that work under high stress and wear conditions. It can replace 40Cr steel when manufacturing parts with a diameter of 80mm; it can also be used after

50Mn2 Alloy Steel

50Mn2 alloy steel

In the quenched and tempered state, 50Mn2 alloy steel can produce parts that work under high stress and wear conditions. It can replace 40Cr steel when manufacturing parts with a diameter of <80mm; it can also be used after normalizing and high temperature tempering to produce medium load and cross-sectional dimensions. Larger parts. For example, main shafts, shafts and large gears in heavy machinery; transmission spline shafts on automobiles and spindles subjected to shock loads; general machinery used as gears, worms, gear shafts, crankshafts, connecting rods, etc. It can also be used as leaf spring and flat coil spring. When manufacturing parts below 80mm, the performance of steel is similar to that of 45Cr steel.

Material name: 50Mn2

Standard: GB/T 3077-1999

Chemical properties

| Grade | Chemical composition(%) | |||||||

| C | Si | Mn | Cr | Ni | Cu | P | S | |

| 50Mn2 | 0.47-0.55 | 0.17~0.37 | 1.40~1.80 | ≤0.30 | ≤0.30 | ≤0.25 | ≤0.025 | ≤0.025 |

Mechanical properties

| Grade | Mechanical properties | |||||

| Tensile strength MPa | Yield strength MPa | Elongation% | Reduction of area% | Impact absorption work Aku2/J | Brinell hardness HBS | |

| 50Mn2 | ≥930 | ≥785 | ≥9 | ≥40 | ≥39 | ≤229 |

Heat treatment Quenching temperature/℃ The first quenching 820 The second quenching-coolant oil

Tempering temperature/℃ 550 Coolant water. Oil

Application

50Mn2 seamless steel pipe is a kind of high-strength medium-carbon quenched and tempered manganese steel. It has high strength, elasticity and wear resistance. At the same time, it has high hardenability. The critical hardenable diameter in oil is 10-28mm. The critical hardening diameter is 24~49mm, and the machinability is fair. This steel can obtain high comprehensive mechanical properties after quenching and tempering, but it has overheating sensitivity and temper brittleness during heat treatment. It also has a tendency to crack during water quenching, and is sensitive to white spots, poor weldability, and low cold deformation plasticity.

Product key description, this is a very good product description, detailing our product use, product characteristics