- ASTM A213/ASME SA213

- China

- Stock

- T5

ASTM A213 T5 Seamless Steel Tube has good heat resistance and corrosion resistance in hot petroleum media, and has good cold and hot processing performance. Therefore, it is widely used in industrial heat exchangers in petrochemical engineer

ASTM A213 T5 Seamless Alloy-Steel Heat-Exchanger Tubes

ASTM A213 ASME SA213 T5 Seamless Alloy-Steel Tubes

T5 steel belongs to the American ASTM A213 standard ferritic steel. It has good heat resistance and corrosion resistance in hot petroleum media, and has good cold and hot processing performance. Therefore, it is widely used in industrial heat exchangers in petrochemical engineering.

Standard: ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A213 T5 Seamless Alloy-Steel Tubes Quick Details

Manufacture:Seamless process ,Cold-drawn

Wall thickness(WT): 0.9 mm-12.7 mm.

Outer diameter (OD): 12.7 mm-127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms: T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished (Outside only) to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

ASTM A213 T5 Seamless Alloy-Steel Tubes Chemical Composition(%)

| Grade | Chemical Composition(%) | ||||||

| C | Mn | P | S | Si | Cr | Mo | |

| A213 T5 | ≤0.15 | 0.30-0.60 | ≤0.025 | ≤0.025 | ≤0.50 | 4.00-6.00 | 0.45-0.65 |

ASTM A213 T5 Seamless Alloy-Steel Tubes Mechanical & Physical Properties

| Grade | Mechanical property | |||

| Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | Hardness(HB) | |

| A213 T5 | ≥415 | ≥205 | 30 | ≤163 |

Grain Size

Grain size shall be as given in Table 1,

Grain size determinations, shall be made on one end of one finished tube from each lot.

Heat Treatment:

ASTM A213 T5 Seamless Alloy-Steel Boiler Tubes shall be reheated for heat treatment in accordance with the requirements of Table 1. Heat treatment shall be carried out separately and in addition to heating for hot forming.

| Grade |

UNS Number |

Heat Treat Type |

Austenitizing/ Solutioning Temperature, min or range ºF [ºC] |

Cooling Media |

Subcritical Annealing or Tempering Temperature, min or range ºF [ºC] |

|

|

ASTM Grain Size No.B |

||||||

| Ferritic Alloy Steels | ||||||

| T5 | K41545 | full or isothermal anneal | … | … | … | … |

| normalize and temper | … | … | 1250 [675] | … | ||

Tests and Inspection

Tension Tests— One tension test shall be made on a specimen from one tube for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes.

Flattening Test—One flattening test shall be made on specimens from each end ofone finished tube, not the one used for the flaring test, from each lot. .

Flaring Test—One flaring test shall be made on specimens from each end of one finished tube, not the one used for the flattening test, from each lot.

Hydrostatic or Nondestructive Electric Test—Each tube shall be subjected to the nondestructive electric test or the hydrostatic test.

Hardness Tests—Brinell, Vickers, or Rockwell hardness tests shall be made on specimens from two tubes from each lot.

Surface Condition

ASTM A213 T5 Seamless Ferritic alloy cold-finished steel tubes shall be free of scale and suitable for inspection. A slight amount of oxidation is not considered scale.

ASTM A213 T5 Seamless Ferritic alloy hot-finished steel tubes shall be free of loose scale and suitable for inspection.

Any special finish requirement be subject to agreement between the supplier and the purchaser.

Process performance and welding performance of ASTM A213 T5 steel

(1) The 5 carbon equivalent is:

m(C) Electricity (T5)=1.58%>0.60%. According to the calculation results, T5 steel has a high tendency to harden, which is a difficult-to-weld material and requires strict process measures such as higher preheating temperature.

(2) Poor welding performance. Due to the tendency of void quenching, the weld and heat-affected zone after welding have high hardness and poor plasticity. Preheat to 250-350℃ before welding. When using chlorine arc welding, the lower limit of preheating temperature can be reduced by 50℃. After welding, cool slowly, avoid cooling to room temperature as much as possible, and go through high temperature tempering at 750-780℃ to improve the mechanical properties of welded joints.

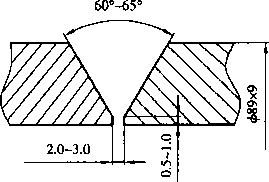

Groove processing of ASTM A213 T5 seamless steel pipe

(1) Since ASTM A213 T5 seamless steel pipes have a strong tendency to harden, the groove should be processed by machining, and the hardened layer at 20mm on the surface and edge of the groove must be polished clean.

(2) The groove form is shown in the figure.

Photos of ASTM A213 T5 Seamless Alloy-Steel Tubes

Product key description, this is a very good product description, detailing our product use, product characteristics