- ASTM A213/ASME SA213

- China

- Stock

- T91

A-213 t91 is ASTM A-213 / A-213m standard steel grade: in 1970s, based on 9Cr-1Mo steel, a new type of ferritic shape steel was formed by adding a small amount of Nb and V microalloying elements and controlling the content of n elements in 9

ASTM A213 T91 Alloy Seamless Steel Pipe

ASTM A213 T91 Seamless Ferritic Alloy-Steel Boiler Tubes

Standard:ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A213 T91 Seamless Ferritic Alloy-Steel Boiler Tubes sizes and thicknesses usually furnished to this specification are 1 ⁄ 8 in. [3.2 mm] in inside diameter to 5 in [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness.

A-213 T91: "A" is the mark of ASTM steel material. "213" refers to the specification reference number, "T91" refers to the steel grade classification, "T" refers to small diameter pipe, equivalent to China's 10Cr9Mo1VNbN small diameter pipe.)

A-213 t91 is ASTM A-213 / A-213m standard steel grade: in 1970s, based on 9Cr-1Mo steel, a new type of ferritic shape steel was formed by adding a small amount of Nb and V microalloying elements and controlling the content of n elements in 9Cr-1Mo steel by several laboratories and burnxiao engineering company in the United States. The steel has good comprehensive mechanical properties, stable structure and properties before and after aging, good welding and technological properties, high endurance strength and oxidation resistance. In 1995, the steel was transplanted into GB5310 standard in China, and the grade was 10Cr9Mo1VNb.

ASTM A213 T91 Seamless Ferritic Alloy-Steel Boiler Tubes Quick Details

Manufacture:Seamless process ,Hot-finished or Cold-finished

Wall thickness(WT): 0.9 mm——12.7 mm.

Outer diameter (OD): 12.7 mm——127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms:T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished (Outside only) to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

Specification of ASTM A213 T91 Boiler Tubes

| OD (mm) | Wall Thickness(mm) | |||||||||||||

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

Materials and Manufacture

ASTM A213 T91 Seamless Ferritic Alloy-Steel Boiler Tubes are made by the seamless process and shall be either hot finished or cold finished, as specified.

Grain Size

Grain size shall be as given in Table 1,

Grain size determinations, shall be made on one end of one finished tube from each lot.

Heat Treatment of ASTM A213 T91

| Grade |

UNS Number |

Heat Treat Type |

Austenitizing/ Solutioning Temperature, min or range ºF [ºC] |

Cooling Media |

Subcritical Annealing or Tempering Temperature, min or range ºF [ºC] |

ASTM Grain S |

| Ferritic Alloy Steels | ||||||

| T91 | K90901 | normalize and temper |

1900–1975 [1040–1080] |

… | 1350–1470 [730–800] | … |

2.ASTM Grain Size No. listed, or coarser, unless otherwise indicated.

Chemical Composition of ASTM A213 T91 Seamless Boiler Tubes

| Chemical Composition(%) | |||||||||||

| C | Mn | P | S | Si | Cr | Mo | V | N | Ni | Al | Nb |

| 0.07-0.14 | 0.3-0.6 | ≤0.02 | ≤0.01 | 0.2-0.5 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.03-0.07 | ≤0.4 | ≤0.04 | 0.06-0.10 |

Mechanical Properties of ASTM A213 T91 Seamless Boiler Tubes

| Low Alloy Steels | ||||||

| Grade |

UNS Designation |

Tensile Strength, min, ksi [MPa] |

Yield Strength, min, ksi [MPa] |

Elongation in 2 in. or 50 mm, min, % |

Hardness | |

| Brinell/Vickers | Rockwell | |||||

| T91 | K90901 | 85 [585] | 60 [415] | 20 |

190 to 250 HBW/ 196 to 265 HV |

90 HRB to 25 |

The dimensional tolerances of ASTM A213 Seamless Boiler Tubes

Tolerances of Wall Thickness

| Wall Thickness, % | ||||||||

|

Outside Diameter in. [mm] |

0.095 [2.4] and Under |

Over 0.095 to 0.150 [2.4 to 3.8], incl |

Over 0.150 to 0.0180 [3.8 to 4.6], incl |

Over 0.180 [4.6] | ||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

| Seamless, Hot-Finished Tubes | ||||||||

|

4 [100] and under |

40 | 0 | 35 | 0 | 33 | 0 | 28 | 0 |

| Over 4 [100] | .... | .... | 35 | 0 | 33 | 0 | 28 | 0 |

| Seamless, Cold-Finished Tubes | ||||||||

| Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

Tolerances of Outside Diameter

| Pecified Outside Diameter,in. [mm] | Permitted Variations, in. [mm] | |

| Over | Under | |

| Hot-Finished Seamless Tubes | ||

| 4 [100] or under | 1 ⁄ 64 [0.4] | 1 ⁄ 32 [0.8] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 1 ⁄ 64 [0.4] | 3 ⁄ 64 [1.2] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 1 ⁄ 64 [0.4] | 1 ⁄ 16 [1.6] |

| Cold-Finished Seamless Tubes | ||

| Under 1 [25] | 0.004 [0.1] | 0.004 [0.11] |

| 1 to 1 1 ⁄ 2 [25 to 40], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [40 to 50], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50 to 65], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [65 to 75], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [75 to 100], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 0.015 [0.38] | 0.045 [1.14] |

Tolerances of Length

|

Method of Manufacture |

Specified Outside Diameter, in.[mm] |

Cut Length, in. [mm] | |

| Over | Under | ||

| Seamless, hot-finished | All sizes | 3 ⁄ 16 [5] | 0 [0] |

| Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

Hydrostatic or Nondestructive Electric Test

Each tube will be subjected to the nondestructive electric test or the hydrostatic test.

Tests

(1)Tension test——One tension test shall be made on a specimen from one tube for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes.

(2)Hardness Requirements—— Brinell, Vickers, or Rockwell hardness tests shall be made on specimens from two tubes from each lot.

(3)Flattening Test——One flattening test shall be made on specimens from each end of one finished tube.

(4)Flaring Test——One flaring test shall be made on specimens from each end of one finished tube.

Surface Condition

Ferritic alloy cold-finished steel tubes are free of scale and suitable for inspection.

Ferritic alloy hot-finished steel tubes are free of loose scale and suitable for inspection.

Note: Material furnished under ASTM A213 conform to the applicable requirements of the current edition of Specification A1016/A1016M

ASTM A213 T91 Seamless Boiler Tubes Marking

In addition to the marking prescribed in Specification ASTM A1016/A1016M, the marking shall indicate whether the tube is hot-finished or cold-finished.

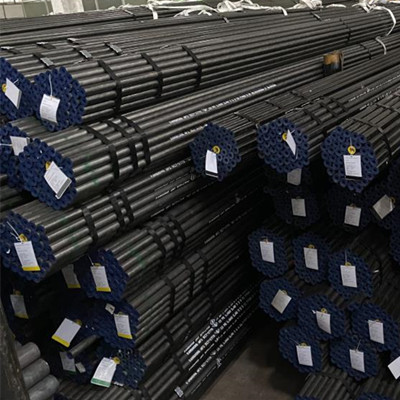

Photos of ASTM A213 T91 Alloy-Steel Boiler Tubes

Product key description, this is a very good product description, detailing our product use, product characteristics