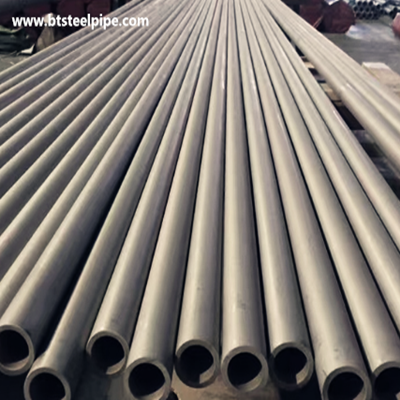

ASTM A790 UNS S31803 Duplex Stainless Steel Pipe

- ASTM A790,ASME SA790

- China

- Stock

- UNSS 31803

ASTM A790 UNS S31803 Steel Pipe covers seamless and straight-seam welded ferritic/austenitic steel pipe intended for general corrosive service, with particular emphasis on resistance to stress corrosion cracking.

ASTM A790 UNS S31803 Duplex Stainless Steel Pipe

ASTM A790 UNS S31803 Duplex Stainless Steel Pipe

Standard Specification for

Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

ASTM A790 UNS S31803 Steel Pipe covers seamless and straight-seam welded ferritic/austenitic steel pipe intended for general corrosive service, with particular emphasis on resistance to stress corrosion cracking.

ASTM A790 UNS S31803 Duplex Stainless Steel Pipe Quick Details

Company Name: Beite steel pipe

Country/Region: China

Product Name:ASTM A790 UNS S31803 Duplex Stainless Steel Pipe

Manufacture:seamless or an automatic welding

Outside Diameter:12.7mm——219mm

Wall thickness:0.9mm——20mm

Length:6000mm、12000m or specified length as require

Port of Shipment:Tianjin,China

Payment:L/C or T/T

Delivery: 7-15 days after payment

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden)

Materials and Manufacture

Manufacture:

The pipes are made by the seamless or an automatic welding process, with no addition of filler metal in the welding operation.

pipe may be either hot-finished or cold-finished.

The pipes are pickled free of scale. When bright annealing is used, pickling is not necessary.

Heat-Treated

all pipe are furnished in the heat-treated condition as shown in Table 1.

TABLE 1 Heat Treatment

|

UNS Designation |

Temperature °F [°C] | Quench |

| S31803 |

1870–2010 [1020–1100] |

Rapid cooling in air or water |

Chemical Composition

|

UNS Designation |

C | Mn | P | S | Si | Ni | Cr | Mo | N |

| S31803 | 0.030 | 2.00 | 0.030 | 0.020 | 1.00 | 4.5–6.5 | 21.0–23.0 | 2.5–3.5 | 0.08–0.20 |

Mechanical Properties

|

UNS Designation |

Type A |

Tensile Strength, min, ksi[MPa] |

Yield Strength, min,ksi [MPa] |

Elongation in 2 in. or 50 mm,min, % |

Hardness, max | |

| HBW | HRC | |||||

| S31803 | 90 [620] | 65 [450] | 25 | 290 | 30 | |

Workmanship, Finish, and Appearance

The finished pipes shall be reasonably straight and shall have a workmanlike finish.

Mechanical Tests Required

Transverse or Longitudinal Tension Test

Mechanical Testing Lot Definition

Flattening Tes

Hardness Test

Hydrostatic or Nondestructive Electric Test

Product Marking

the marking include the manufacturer’s private identifying mark and whether the pipe is seamless or welded. If specified in the purchase order, the marking for pipe larger than NPS 4 shall include the weight.

Ordering Information

1.1 Quantity (feet, [metres], or number of lengths),

1.2 Name of material (ferritic/austenitic steel pipe),

1.3 Process (seamless or welded),

1.4 Grade (UNS S31803),

1.5 Size (NPS designator or outside diameter and schedule number of average wall thickness),

1.6 Length (specific or random) ,

1.7 End finish (section on ends of Specification A999/A999M),

1.8 Test report required (section on certification of Specification A999/A999M),

1.9 Specification designation, and

Product key description, this is a very good product description, detailing our product use, product characteristics