- GB/T1299

- China

- Stock

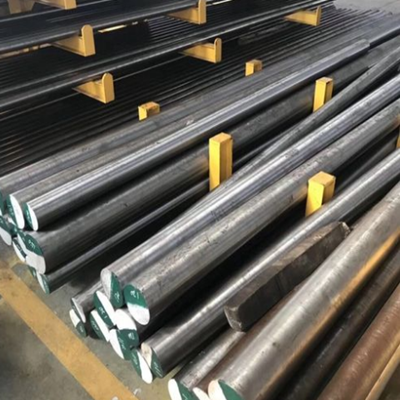

- H13 steel

H13 steel H13 belongs to hot work die steel, which is a steel grade formed by adding alloying elements on the basis of carbon steel, which implements the standard GB/T1299-2014. The unified digital code of H13 steel is T23353; the brand is

H13 steel

H13 steel

H13 belongs to hot work die steel, which is a steel grade formed by adding alloying elements on the basis of carbon steel, which implements the standard GB/T1299-2014.

The unified digital code of H13 steel is T23353; the brand is 4Cr5MoSiV1. It has good comprehensive performance at medium temperature (~600°), high hardenability (hardenable in air), low heat treatment deformation rate, and its performance and service life are higher than 3Cr2W8V. It can be used for forging hammer forging dies, aluminum alloy die casting dies, hot extrusion dies, high-speed precision forging dies and forging press dies, etc.

Chemical composition

| Grade | Chemical composition(%) | |||||||

| C | Si | Mn | Cr | Mo | V | P | S | |

| H13 steel | 0.32~0.45 | 0.80~1.20.. | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 | ≤0.03 | ≤0.03 |

Mechanical properties

Hardness: Annealing, 245~205HB, quenching, ≥50HRC

Delivery status

Brinell hardness HBW10/3000 (≤229))

Main features

H13 steel is the most widely used and most representative hot work die steel. Its main characteristics are:

(1) Has high hardenability and high toughness;

(2) Excellent thermal crack resistance, water cooling can be used in the work place;

(3) With moderate wear resistance, carburizing or nitriding processes can also be used to increase the surface hardness, but the thermal crack resistance should be slightly reduced;

(4) Because of its low carbon content, the secondary hardening ability during tempering is poor;

(5) It has the ability to resist softening at a higher temperature, but the hardness drops rapidly when the use temperature is higher than 540°C (1000°F) (that is, the capable working temperature is 540°C);

(6) The deformation of heat treatment is small;

(7) Medium and high machinability;

(8) Medium resistance to decarburization.

What is more noticeable is that it can also be used to make important components in the aviation industry.

Application of H13 steel

The use is basically the same as 9CRWMN die steel, but because of its higher vanadium content, the medium temperature (600 degrees) performance is better than 4Cr5MoSiV steel. It is a representative steel grade with a wide range of uses in hot work die steel.

H13 die steel is used to manufacture forging dies with high impact load, hot extrusion dies, precision forging dies; die-casting dies for aluminum, copper and their alloys.

Quenching: 790 degrees +-15 degrees preheating, 1000 degrees (salt bath) or 1010 degrees (furnace control atmosphere) +-6 degrees heating, heat preservation 5~15min air cooling, 550 degrees +-6 degrees tempering; annealing, hot processing ;

H13 steel related knowledge

H13 steel is C-Cr-Mo-Si-V steel, which is widely used in the world. At the same time, many scholars from various countries have conducted extensive research on it and are exploring the improvement of chemical composition. Steel is widely used and has excellent characteristics, mainly determined by the chemical composition of steel. Of course, the impurity elements in the steel must be reduced. Data shows that when the Rm is 1550MPa, the sulfur content of the material is reduced from 0.005% to 0.003%, which will increase the impact toughness by about 13J. The NADCA 207-2003 standard stipulates that the sulfur content of premium H13 steel should be less than 0.005%, while the sulfur content of superior should be less than 0.003%S and 0.015%P. The composition of H13 steel is analyzed below.

Carbon: American AISI H13, UNS T20813, ASTM (the latest edition) H13 and FED QQ-T-570 H13 steel have carbon content of (0.32~0.45)%, which is the most carbon content range of all H13 steels. Wide. The carbon content of German X40CrMoV5-1 and 1.2344 is (0.37~0.43)%, and the carbon content range is narrow. In German DIN17350, the carbon content of X38CrMoV5-1 is (0.36~0.42)%. The carbon content of SKD 61 in Japan is (0.32~0.42)%. The carbon content of 4Cr5MoSiV1 and SM 4Cr5MoSiV1 in my country's GB/T 1299 and YB/T 094 is (0.32~0.42)% and (0.32~0.45)%, which are the same as SKD61 and AISI H13, respectively. In particular, it should be pointed out that the carbon content of H13 steel in the standards of North American Die Casting Association NADCA 207-90, 207-97 and 207-2003 are all stipulated as (0.37~0.42)%.

The carbon content of the steel determines the hardness of the hardened steel matrix. According to the relationship curve between the carbon content of the steel and the hardness of the quenched steel, it can be known that the quenching hardness of H13 steel is about 55HRC. For tool steel, part of the carbon in the steel enters the steel matrix to cause solid solution strengthening. Another part of carbon will combine with carbide forming elements in alloying elements to form alloy carbides. For hot work die steels, in addition to a small amount of residual carbides, this alloy carbide is required to be dispersed and precipitated on the quenched martensite matrix during the tempering process to produce two hardening phenomena. Therefore, the uniform distribution of residual alloy carbon compounds and tempered martensite determines the performance of hot work die steel. This shows that the C content in steel cannot be too low.

H13 steel containing 0.5% Cr should have high toughness, so its C content should be maintained at a level that forms a small amount of alloy C compounds. Woodyatt and Krauss pointed out that on the Fe-Cr-C ternary phase diagram at 870℃, the position of H13 steel is better at the junction of the austenite A and (A+M3C+M7C3) three-phase regions. The corresponding C content is about 0.4%. The figure also marked the increase in the amount of C or Cr to increase the amount of M7C3, and A2 and D2 steels with higher wear resistance for comparison. It is also important to keep the C content relatively low so that the Ms point of the steel is set at a relatively high temperature level (the Ms of H13 steel is generally described as 340℃), so that the steel can be quenched to room temperature. Obtain the alloy C compound structure mainly composed of martensite plus a small amount of residual A and the remaining uniformly distributed alloy, and obtain a uniform tempered martensite structure after tempering. Avoid transforming too much retained austenite at the working temperature to affect the working performance or deformation of the workpiece. These small amounts of retained austenite should be completely transformed in the two or three tempering processes after quenching. By the way, it is pointed out here that the martensite structure obtained after quenching of H13 steel is lath M + a small amount of flake M + a small amount of residual A. Domestic scholars have also done some work on the very fine alloy carbides precipitated on the lath M after tempering.

Product key description, this is a very good product description, detailing our product use, product characteristics