- China

- Stock

- DZ125(DZ4125) Steel

DZ125(DZ4125) Steel DZ125 (DZ4125) nickel-based precipitation hardening type directionally solidified columnar superalloy Overview of DZ125 Steel: DZ125 steel is a nickel-based precipitation hardening type directionally solidified columnar

DZ125(DZ4125) Steel

DZ125(DZ4125) Steel

DZ125 (DZ4125) nickel-based precipitation hardening type directionally solidified columnar superalloy

Overview of DZ125 Steel:

DZ125 steel is a nickel-based precipitation hardening type directionally solidified columnar high-temperature alloy steel. The service temperature is below 1050°C. It is one of the alloys with the highest performance level among similar alloys in my country. The alloy has good comprehensive properties at middle and high temperature and excellent fatigue resistance. The alloy is based on the composition of René 125 alloy in the United States by adjusting the content of titanium element and adding hafnium element, so that the alloy has good casting performance, and can be cast into a directional solidification without margin with a complex cavity with a wall thickness as small as 0.5mm. blade. It is suitable for making high temperature parts such as gas turbine rotor blades and guide vanes.

Equivalent grades of DZ125 steel:

DZ4125, DS René125

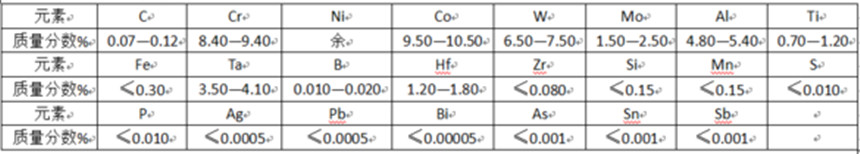

Chemical composition of DZ125 steel

Mechanical properties of DZ125 steel

|

Yield Rp0.2 (MPa) |

Tensile Rm (MPa) |

Impact KV/Ku (J) |

Elongation A (%) |

Reduction in cross section on fractureZ (%) | As-Heat-Treated Condition | Brinell hardness (HBW) |

| 982 (≥) | 883 (≥) | 14 | 21 | 22 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 241 |

DZ125 material technical standard:

GB/T 14992 Classification and designation of high temperature materials for high temperature alloys and intermetallic compounds

HB 7762 Specification for Directionally Solidified Columnar and Single Crystal Superalloy Ingots for Aeroengine

HB/Z 140 high temperature alloy heat treatment process for aviation

Q/6S 1321 DZ125 and DZ125L alloy high pressure turbine working blade castings

Melting and casting process of DZ125 steel:

The master alloy is smelted in a vacuum induction furnace, and the directional solidification test bar and parts are remelted and poured in the vacuum directional solidification furnace.

Application overview and characteristics of DZ125 steel:

The alloy has been used extensively in the production of directional hollow turbine rotor blades with no margin for an advanced aero-engine, and the blades are in good batch production and use.

The alloy can be treated with a variety of surface protective coatings. The advanced vacuum arc plating NiCrAlYSi cladding coating has been adopted, which significantly improves the alloy's resistance to oxidation and heat corrosion. After long-term aging of the alloy at 900℃ for 4000h, no TCP phase was precipitated.

Product key description, this is a very good product description, detailing our product use, product characteristics