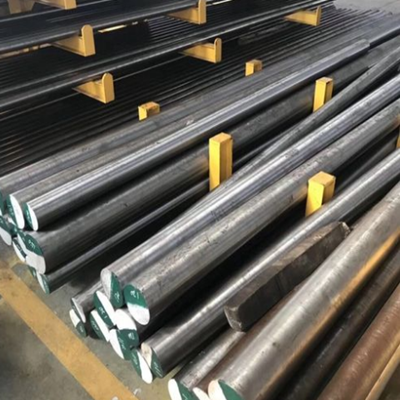

4Cr3Mo2NiVNb (HD) steel

- China

- Stock

- 4Cr3Mo2NiVNb

4Cr3Mo2NiVNb (HD) steel The code name of 4Cr3Mo2NiVNb steel is HD steel. It is an air-cooled hardened martensitic hot work die steel. It is a new type of heat developed by Huazhong University of Science and Technology on the basis of QRO-80

4Cr3Mo2NiVNb (HD) steel

4Cr3Mo2NiVNb (HD) steel

The code name of 4Cr3Mo2NiVNb steel is HD steel. It is an air-cooled hardened martensitic hot work die steel. It is a new type of heat developed by Huazhong University of Science and Technology on the basis of QRO-80 steel in Uddholm, Sweden. For die steel.

01 Chemical composition (%)

| C | 0.35~0.45 | Cr | 2.50~3.00 |

| Si | ≤0.35 | Mo | 1.80~2.20 |

| Mn | ≤0.40 | Ni | 0.80~1.20 |

| P | ≤0.030 | V | 1.00~1.40 |

| S | ≤0.030 | Nb | 0.10~0.25 |

02 Critical point

Ac1=789℃, Ac3=910℃, Ms=363℃

03Heat processing

HD steel forging process specification

| Project | Steel ingot | Billet |

| Heating temperature℃ | 1140~1180 | 1120~1160 |

| Initial forging temperature℃ | 1080~1140 | 1060~1120 |

| Final forging temperature℃ | ≥900 | ≥850 |

| Cooling method | Sand or pits slowly cool | Sand or pits slowly cool |

04Preparation heat treatment

Isothermal annealing of forging materials: <500℃ into the furnace and then heating up, heating temperature 830~850℃, holding time (H) 1+1min/mm, isothermal temperature 730±10℃, holding time (H) 2+1min/mm, Cooled with the furnace to <500℃ and air-cooled out of the furnace (HB≤250).

05Quenching Specification

The quenching temperature is 1130±10℃, oil cooling.

The relationship between HD steel quenching temperature and hardness and grain size

| Quenching temperature/℃ | Hardness HRC | Grain size/level |

| 1050 | 50.5 | — |

| 1100 | 53.5 | 11 |

| 1130 | 53.5 | 10 |

| 1160 | 56.0 | 8~9 |

| 1180 | 56.0 | 7~8 |

| 1200 | 56.5 | 7~8 |

Hardness value of HD steel tempered at different temperatures

| Tempering temperature/℃ | Hardness HRC | |

| HD steel | 3Cr2W8V steel | |

| 300 | 52.5 | 51.0 |

| 400 | 52.0 | 51.0 |

| 500 | 52.5 | 51.4 |

| 530 | 53.5 | 52.3 |

| 560 | 54.0 | 51.5 |

| 590 | 53.8 | 51.8 |

| 620 | 51.2 | 50.0 |

| 650 | 47.0 | 46.0 |

| 700 | 41.0 | 34.0 |

06 Mechanical properties (compared with 3Cr2W8V steel)

Room temperature mechanical properties of HD steel

| Heat treatment process | σ0.2/MPa | ψ(%) | αk/(J/cm2) | |||

| HD | 3Cr2W8V | HD | 3Cr2W8V | HD | 3Cr2W8V | |

| 1130℃ quenching, 650℃ tempering | 1633 | 1463 | 32.4 | 41.8 | 38.8 | -- |

| 1130℃ quenching, 700℃ tempering | 1165 | 952 | 45.7 | 41.9 | 48.8 | -- |

High temperature mechanical properties of HD steel

|

Test temperature |

σ0.2/MPa | ψ(%) | αk/(J/cm2) | |||

| HD | 3Cr2W8V | HD | 3Cr2W8V | HD | 3Cr2W8V | |

| 650℃ | 536.9 | 414 | 66.1 | 49.1 | 56/54 | -- |

| 700℃ | 405.3 | 235 | 69.3 | 85.4 | 75/40 | 62/38 |

Note: The denominator in the αk value is the hardness value (HRC)

07 Performance characteristics

4Cr3Mo2NiVNb (HD) steel is based on 4Cr3Mo3V steel. By reducing the content of Mo and V, adding 1% Ni and 0.15% Nb, the room temperature and high temperature toughness and thermal stability of the steel are improved. Can maintain the hardness of 40HRC. Under the same hardness conditions, HD steel has 50% higher fracture toughness than 3Cr2W8V steel, 70% higher tensile strength at 700°C, and double and 50% higher thermal fatigue resistance and thermal wear resistance.

08 Applications

The comprehensive performance of HD steel is good. It is suitable for the production of hot work molds with a heating temperature of about 700°C and harsh use conditions, such as hot extrusion dies for ferrous and non-ferrous materials, hot precision forging dies, etc., for hot extrusion of steel pipes The use of punches, copper alloy pipe extrusion bottom molds and perforation needles, hot extrusion bearing ring punch and female molds, valve extrusion bottom molds and other molds have a significantly longer service life than 3Cr2W8V steel.

Product key description, this is a very good product description, detailing our product use, product characteristics