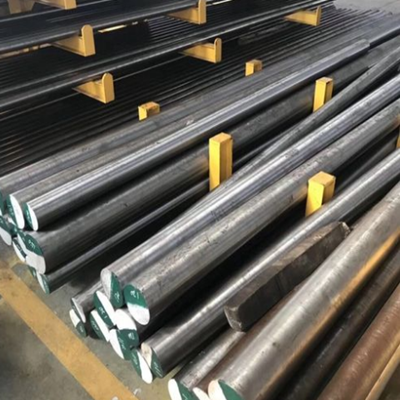

25CRMO Round Steel

- China

- Stock

- 25CRMO Steel

25CRMO round steel 1.25CRMO round steel reference standard GB19189 Quenched and tempered high-strength steel plate for pressure vessel GB713 Steel Plate for Boiler and Pressure Vessel The sample sampling method for chemical composition anal

25CRMO Round Steel

25CRMO round steel

1.25CRMO round steel reference standard

GB19189 Quenched and tempered high-strength steel plate for pressure vessel

GB713 Steel Plate for Boiler and Pressure Vessel

The sample sampling method for chemical composition analysis of GB/T222 steel and the allowable deviation of the chemical composition of the finished product

GB/T223 Steel and alloy chemical analysis methods

GB/T228 Metallic materials Tensile test method at room temperature

GB/T232 Metallic materials bending test method

GB/T229 Charpy impact test method for metals

GB/T2975 Steel and steel product mechanical performance test sampling location and sample preparation

GB/T709 Hot-rolled steel plate and strip size, shape, weight and allowable deviation

GB/T247 General provisions for acceptance, packaging, marking and quality certificates of steel plates and strips

NB/T47013 Non-destructive testing of pressure equipment

NB/T47014 welding procedure qualification for pressure equipment

2.25 CRMO round steel technical conditions

(1) 25CRMO round steel-SR size, shape, quality and allowable deviation

The size, shape, quality and allowable deviation of 25CRMO -SR steel plate are in accordance with GB19189 and GB/T709. Among them, the unevenness of the steel plate along the width direction: the steel plate with a thickness of ≥20mm shall not exceed 6/1000, and the steel plate with a thickness of <20mm shall not exceed 8/1000. And the negative deviation of the steel plate thickness is 0, and the thickness tolerance zone is moved up by 0.25mm as a whole. The theoretical quality calculation method of steel plate is increased by 0.125mm on the basis of the additional value of thickness specified in the GB19189 standard.

(2) Chemical composition of 25CRMO round steel

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo | V | Ceq | Pcm | PsR |

| 25CRMO |

≤ 0.15 |

0.15-0.40 | 1.20-1.60 |

≤ 0.015 |

≤ 0.008 |

0.15-0.40 |

≤ 0.30 |

≤ 0.30 |

0.02-0.06 |

≤ 0.43 |

≤ 0.24 |

< 0.00 |

Note: 1) Ceq(%)=C+Mn/6+Si/24+Ni/40+Cr/5+Mo/4+V/14(%)

2) Pcm(%)=C+Si/30+Mn/20+Cu/20+Ni/60+Cr/20+Mo/15+V/10+5B

3) PsR(%)=Cr+Cu+2Mo+10V+7Nb+5Ti-2 (only for -SR steel plate)

(3) Mechanical properties of 25CRMO round steel

| Tensile test | Impact test | Cold bending test | ||||||

| Yield strength | Tensile strength | Yield to strength ratio | Elongation % | Test temperature (℃) | Sample shape | Three averages (J) | Single lowest (J) |

180˚ b=2a |

| ≥490 | 610-730 | ≤0.91 | ≥17 | -20 |

2mm V型 |

≥80 | ≥56 | d=3a |

(4) 25CRMO round steel quenched and tempered heat treatment

All 25CRMO is delivered in quenched and tempered (quenched + tempered) state, and the final tempering temperature of 12MnNiVR-SR steel plate is not less than 620℃.

(5) Surface quality of 25CRMO round steel

The surface quality of 25CRMO steel plate is implemented in accordance with the provisions of GB19189, and welding repair is not allowed on the surface of the steel plate.

(6) Ultrasonic testing of 25CRMO round steel

25CRMO is all tested by NB/T47013 one by one ultrasonic testing (dual crystal probe can be used), and the qualified level is level I.

(7) 25CRMO round steel welding conditions

25CRMO steel plate shall meet the requirements of the following table for the mechanical properties of the welded joint after the oil tank has been welded by gas-electric vertical welding (heat input not exceeding 100KJ/cm), submerged arc welding, manual welding, and gas shielded welding. The test methods and requirements should meet the requirements of NB/T47014.

| Tensile test | Impact test | Cold bending test | ||||

| Yield strength | Tensile strength | Test temperature | Sample shape | Three averages (J) | Single lowest (J) | Conform to JB4708 |

| ≥490 | 610-730 | -20℃ | 2mm V型 | ≥47 | ≥33 | |

3.25 CRMO round steel test method

The inspection items, sampling quantity, sampling method, and test method of 25CRMO round steel plate shall meet the requirements of the following table:

| Number | Inspection items | Sampling quantity (piece / piece) | Sampling method | Test method |

| 1 | Surface | One by one | / | Visual inspection |

| 2 | Size | One by one | / | Measuring tools |

| 3 | Chemical composition | Tank number of each furnace | GB/T 222 | GB/T223 |

| 4 | Stretching | Heat treatment sheet by heat |

GB19189 GB/T2975 |

GB/T228 |

| 5 | Cold bend | Heat treatment sheet by heat | GB/T232 | |

| 6 | Impact | 3 samples (heat treated piece by piece) | GB/T229 | |

| 7 | Ultrasonic testing | One by one | / | NB/T47013 |

Note: The sampling position is 1/4 of the plate width; the direction of the sample is all transverse, and the axis of the impact sample is located at 1/4 of the plate thickness or as close to 1/4 as possible.

4.25 CRMO round steel R packaging, marking and quality certificate

The supplied round bars shall be marked with the following items in an appropriate way:

Name of the steel plate manufacturer; 2) steel number; 3) furnace batch number; 4) size; 5) SR mark.

The quality certificate of each round steel supplied shall at least include the following contents:

1) Name of the steel plate manufacturer; 2) Steel number; 3) Furnace batch number; 4) Chemical composition; 5) Mechanical properties; 6) Ultrasonic test results; 7) Mark of quality inspection department; 8) Final tempering temperature of steel plate, if If the number of heat treatments exceeds one time, the number of heat treatments should be indicated.

5.25 CRMO round steel surface treatment

25CRMO round steel plate is supplied without surface treatment and painting.

Product key description, this is a very good product description, detailing our product use, product characteristics