1.2344 tool steel

- China

- Stock

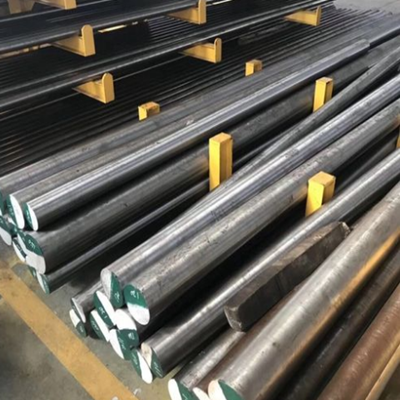

- 1.2344 tool steel

1.2344 tool steel 1.2344 steel is pressure-resistant hot-worked tool steel. The steel is electroslag remelted, with uniform material, good hardenability, excellent machining performance and polishing performance, high toughness and plastici

1.2344 tool steel

1.2344 tool steel

1.2344 steel is pressure-resistant hot-worked tool steel. The steel is electroslag remelted, with uniform material, good hardenability, excellent machining performance and polishing performance, high toughness and plasticity, good high and low temperature wear resistance, high temperature fatigue resistance and heat resistance.

Name: 1.2344 tool steel

Forging temperature: 1050-850℃

Softening annealing temperature: 820-840℃

Hardening temperature: 1020-1050℃

Tempering temperature: 520-700℃

Features of 1.2344 tool steel

1. Uniform material, superior machinability and polishing,

2. High toughness and high plasticity,

3. High wear resistance at high and low temperatures,

4. Excellent overall hardening,

5. Good high temperature strength and heat fatigue resistance.

6. Very low deformation during heat treatment,

7. Compared with traditional steel, it has better isotropy and excellent toughness and plasticity in all directions.

Chemical properties

| Grade | Chemical properties(%) | |||||||

| C | Si | Mn | P | S | Cr | Mo | V | |

| 1.2344 tool steel | 0.37~0.42 | 0.90~1.20 | 0.30~0.50 | ≤0.030 | ≤0.030 | 4.80~5.50 | 1.20~1.50 | 0.90~1.10 |

Mechanical behavior

| Grade | Tensile strength, ultimate (@20°C/68°F, varies with heat treatment)MPa | Tensile strength, ultimate (@20°C/68°F, varies with heat treatment)MPa | Reduction of area (@20°C/68°F) | Modulus of elasticity (@20°C/68°F)Gpa | Poisson’s ratio |

| 1.2344 tool steel | 1200-1590 | 1000-1380 | 50% | 215 | 0.27-0.30 |

Heat treatment

Forging temperature: 1050-850℃

Softening annealing temperature: 820-840℃

Hardening temperature: 1020-1050℃

Tempering temperature: 520-700℃

Purity: According to ASTM E45 method A, A sulfide≤0.5, B oxide, C silicate and D spherical oxide each≤1 or DIN 50602-K1≤10 or according to customer requirements.

Delivery state of steel: soft annealed, good microstructure, hardness up to 229HB or quenched and tempered to customer requirements.

Specification for isothermal annealing

Annealing temperature (850±10)°C, holding for 2h, cooling with furnace to (720±10)°C, holding for 4h, furnace cooling to below 500°C, out-of-furnace air cooling, hardness ≤229HBW.

High temperature tempering specification

Tempering temperature (730 ±10)°C, heat preservation 2h, furnace cooling ≤500°C, air cooling after furnace.

Quenching and tempering specifications

Quenching temperature 850 ~880°C, oil cooling, hardness 50 ~52HRC; tempering temperature 580 ~640°C, air cooling, hardness 28 ~36HRC

Pre-hardening treatment specification

Heating temperature 860 ~900°C, oil cooling, tempering temperature 570 ~70O°C, air cooling, tempering hardness 28~35HRC.

Usage status

30-56HRC.

State supply: flat steel YB/T 094-1997 for plastic moulds stipulates: flat steel width 170 ~ 410mm, thickness 25 ~ 105mm. Can be supplied under the hardness of 29.5 ~35HRC. Pre-hardened state, hardness ≤28HRC; Annealed state, hardness ≤22HRC

Ultrasonic inspection

ASTM A388-FBH max.3mm(1/8inch) or SEP 1921-test group3-ciassE, e or according to customer requirements.

Main application

1. Die casting mold (mold core, fixed parts, upper mold, nozzle, nitriding thimble,)

2. Extrusion die (mold core, support, baffle block,)

3. Hot pressing mold, (aluminum, magnesium, copper alloy,)

4. Parts, such as cold shear, flash, hot shear, wear-resistant parts,

Equivalent grade

Equivalent grade

| USA | Germany | China | Japan | France | England | Italy |

| ASTM/AISI/SAE/UNS | DIN,WNr | GB | JIS | AFNOR | BS | UNI |

| H13 / T20813 | X40CrMoV5-1/ 1.2344 | 4Cr5MoSiV1 | SKD61 | X40CrMoV5/Z40CDV5 | BH13 | X40CRMOV511KU |

Product key description, this is a very good product description, detailing our product use, product characteristics