What does TS mean on seamless steel pipes?

What does TS mean on seamless steel pipes?

TSG D2001-2006 Pressure Pipeline Element Manufacturing License Regulations

License mark and its application

Ⅰ、 License tag style

As shown in the figure below:

II. Font and size of license mark

The approval mark "ts" shall be in font different from the color of the pressure pipe element base. The size of the mark can be determined according to the size of the element, but the minimum diameter shall not be less than 5mm, generally 10 mm, 15 mm, 20 mm, etc.

III. application of license mark

The following requests shall be complied with:

(1) the manufacturing unit that is licensed to apply the license mark shall affix (spray, engrave, steel seal, etc.) the license mark on each pressure pipe element (completed or pressure pipe element and assembly in the final evaluation condition) in a clearly identifiable and indelible way, and the license mark shall affix (spray, engrave, steel seal, etc.) )In a clearly visible position, neat and clear;

(2) the license number of the manufacturer must be indicated after the license mark (may not include the year);

Hengyang Hualing Steel Pipe Co., Ltd

Pressure pipeline component number:TS2710G86-2012

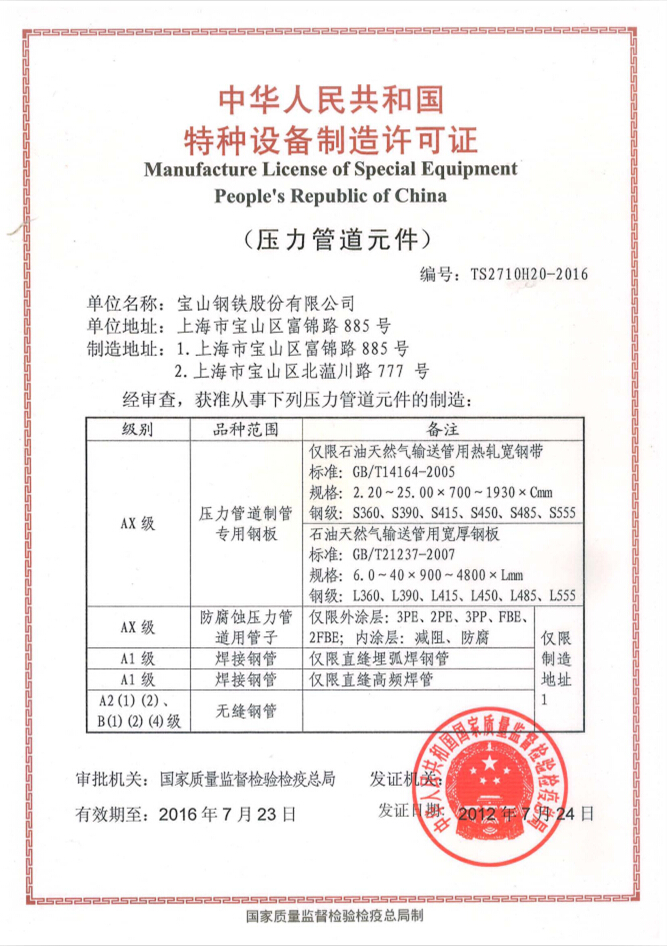

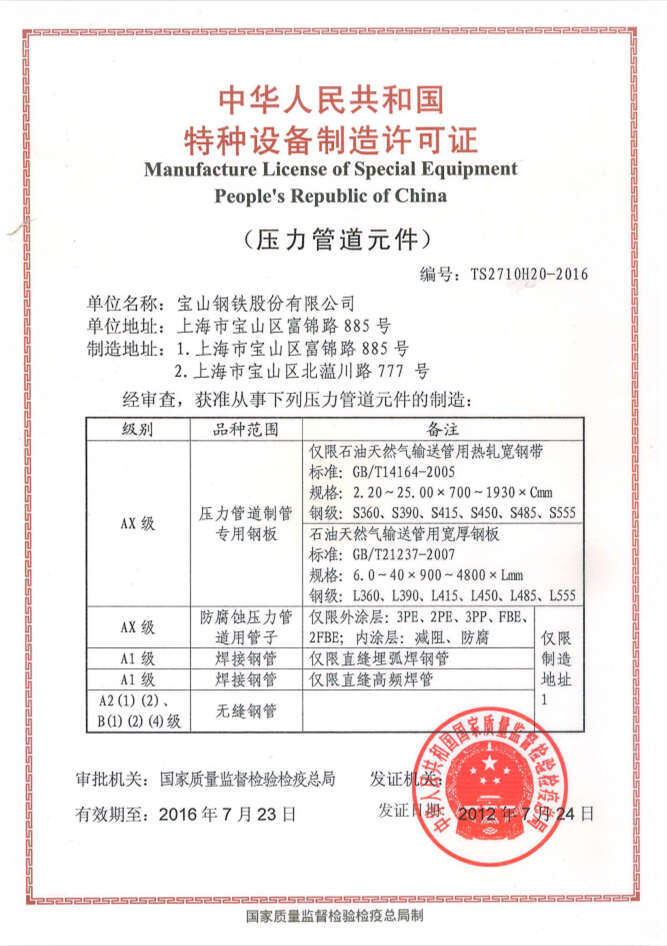

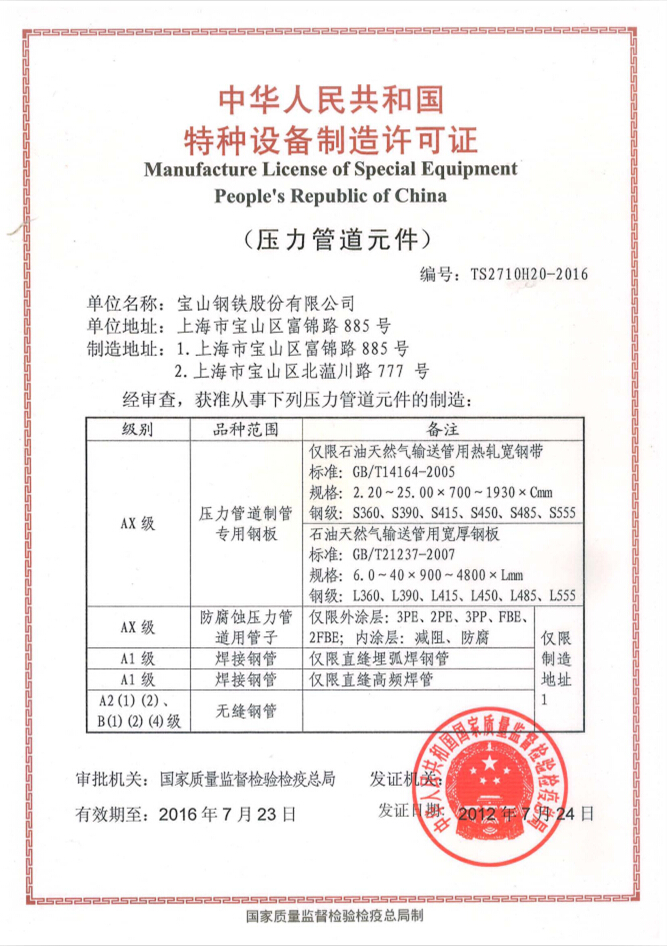

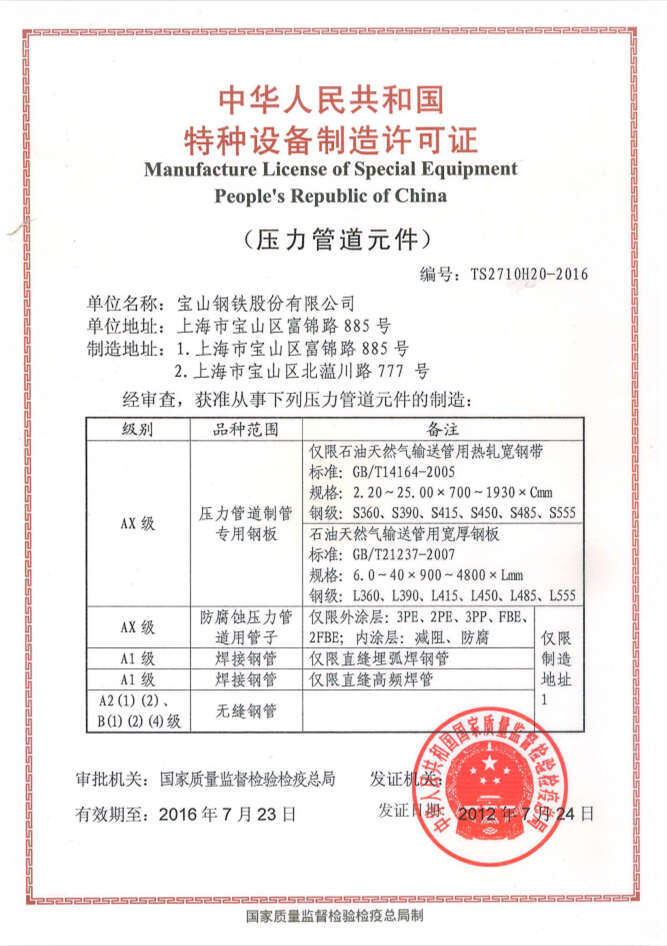

Baoshan Iron and Steel Co., Ltd

Pressure pipeline component number::TS2710H20-2016

(3) Each component constituting the assembly can be labeled with a license mark without any distinction. If the component has been labeled with a license mark when assembling the assembly, the license mark can be carried continuously after assembly;

(4) Other marks that may mislead the meaning or situation of the license mark shall not be attached to the pressure pipe components or assemblies. If other marks are attached, it must be ensured that the visibility and clarity of the license mark will not be reduced.

IV. other requests

(1) when there is a request for Enron technical specifications, the license mark shall also be attached with the number of the testing institution involved in the supervision and test, and the numbering method and method shall be confirmed according to Enron technical specifications.

(2) the manufacturer shall stipulate the pattern and specific application method of the license mark in the quality control manual.

TSG D2001-2006 Pressure Pipeline Element Manufacturing License Regulations

| Licensing project | Scope of representative products | Restricted scope | |

| Variety (product) | level | ||

| Seamless steel tube | A1 | Seamless steel pipe with nominal diameter greater than or equal to 200mm |

Materials, Specifications, standard |

| A2 |

(1) Seamless steel pipe for gas cylinder of boiler pressure vessel with nominal diameter less than 200mm; (2) Seamless steel pipe for oil and gas transmission pipeline and oil (gas) well (casing) pipe with nominal diameter less than 200mm |

||

| B |

(1) Other seamless steel pipes with nominal diameter greater than 25mm; (2) Various tube blanks |

||

License mark and its application

Ⅰ、 License tag style

As shown in the figure below:

II. Font and size of license mark

The approval mark "ts" shall be in font different from the color of the pressure pipe element base. The size of the mark can be determined according to the size of the element, but the minimum diameter shall not be less than 5mm, generally 10 mm, 15 mm, 20 mm, etc.

III. application of license mark

The following requests shall be complied with:

(1) the manufacturing unit that is licensed to apply the license mark shall affix (spray, engrave, steel seal, etc.) the license mark on each pressure pipe element (completed or pressure pipe element and assembly in the final evaluation condition) in a clearly identifiable and indelible way, and the license mark shall affix (spray, engrave, steel seal, etc.) )In a clearly visible position, neat and clear;

(2) the license number of the manufacturer must be indicated after the license mark (may not include the year);

Hengyang Hualing Steel Pipe Co., Ltd

Pressure pipeline component number:TS2710G86-2012

Baoshan Iron and Steel Co., Ltd

Pressure pipeline component number::TS2710H20-2016

(3) Each component constituting the assembly can be labeled with a license mark without any distinction. If the component has been labeled with a license mark when assembling the assembly, the license mark can be carried continuously after assembly;

(4) Other marks that may mislead the meaning or situation of the license mark shall not be attached to the pressure pipe components or assemblies. If other marks are attached, it must be ensured that the visibility and clarity of the license mark will not be reduced.

IV. other requests

(1) when there is a request for Enron technical specifications, the license mark shall also be attached with the number of the testing institution involved in the supervision and test, and the numbering method and method shall be confirmed according to Enron technical specifications.

(2) the manufacturer shall stipulate the pattern and specific application method of the license mark in the quality control manual.