Six connection methods of steel pipe and pipeline

Six connection methods of steel pipe and pipeline

Steel pipe and pipeline connection is a very important part of the project construction, directly related to the quality of the project. With the rapid development of pipeline industry, there are more and more methods to connect the pipeline. In this paper, 6 kinds of connection methods are sorted out for reference.

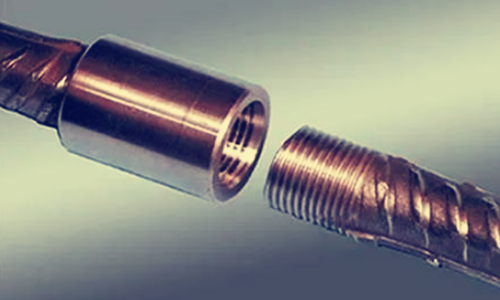

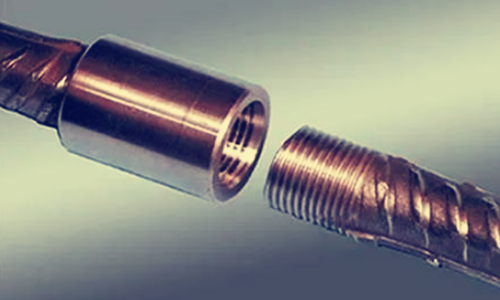

Threaded connection

1. Thread processing

It shall be cut in 2-3 times, and the thread shall be clear, complete and smooth without burr and disordered wire. If there is any broken or missing thread, it shall not be greater than 10% of the total thread thread number. The thread shall also meet the requirements of assembly tolerance, with a taper of 1 / 16, to prevent too loose or too tight fit between threads.

GB / t7306, 55 ° sealing pipe thread, is applicable to the threaded connection of pipes, valves, pipe joints, cocks and other pipe accessories.

2. Thread assembly

After tightening, 2-3 thread tails shall be exposed, excess packing shall be removed, and exposed thread teeth shall be painted with red lead for rust prevention. The painting width of red lead is the same, and the coating is uniform without flowing or missing.

3. Common problems

The hemp thread is not cleaned, the exposed thread is long, the painting is standard, and the painting is free of rust

Flange connection

1. Pipe flange

1) The specification and model of companion flange are the same; when connecting with equipment flange, it shall be matched according to its specification;

2) When the flange is connected, it is coaxial and parallel, and the flange surface is perpendicular to the pipe center;

3) The specification of the fastening bolt is the same, the direction is the same, the exposed length of the bolt is 1 / 2 of the bolt diameter or flush with the nut;

4) When connecting the valve, the nut shall be placed on the valve side;

5) The top two screw holes of the horizontal pipe flange shall be kept horizontal, and the two screw holes of the vertical pipe flange against the wall shall be parallel to the wall.

Flange standard: national standard gb9112-9123, Ministry of machinery standard jb79-86, Ministry of chemical industry standard hg5008-5028 and Ministry of petroleum industry standard syj4, the flange bolt hole center is the same, the pipe diameter of JB standard and Hg standard is "small outer diameter", GB standard and SYJ standard are "large outer diameter", when using, it should be noted that the number of bolt holes of individual specification flange is different.

2. Common problems

Inner ring of flange is not welded, inner ring of flange is not welded, flange does not match

Welded connection

1. Welding

1) The welding of stainless steel pipe is protected by argon filling. After welding, the weld and heat affected zone are pickled and passivated.

2) The brazing of copper pipe shall not be over heated (650-750 ℃), and the residual slag and other sundries at the welding joint shall be removed after welding.

3) No undercut, slag inclusion, crack, splash and other defects are found in the weld appearance inspection.

2. Common problems

The brazed joint of copper pipe is not cleaned, the undercut of stainless steel pipe is not treated, the width of weld is narrow, and the reinforcement is different

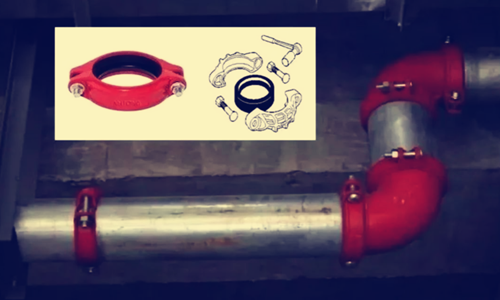

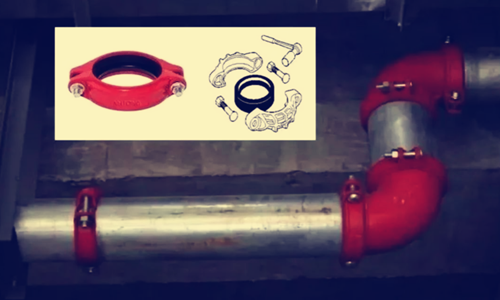

Groove connection

1. Groove assembly

1) Clean the pipe end, put on the rubber sealing ring, install the clamp and fasten the bolt;

2) The center line of the pipe at the two ends of the trench is the same, and the installation direction (fastening bolt position) of the trench is the same;

3) The straight pipe section should adopt rigid joint, and a flexible joint should be set between every 4-5 continuous rigid joints on the pipe section.

2. Common problems

The direction of groove joint is not uniform, and the pipes at both ends of groove are not straight.

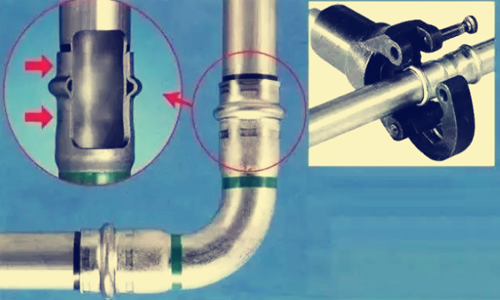

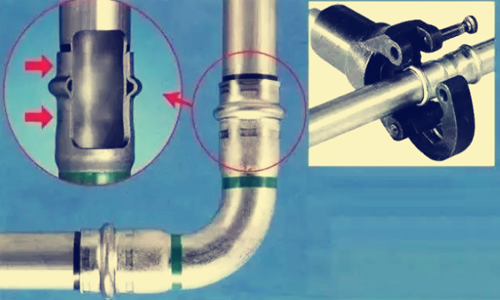

Compression connection

Clean the insertion port and mark the insertion depth. Insert the pipe to the specified depth and keep the axis vertical. Use the special clamping tool to clamp the joint, and use the gauge to check whether the clamping dimension is in place after clamping.

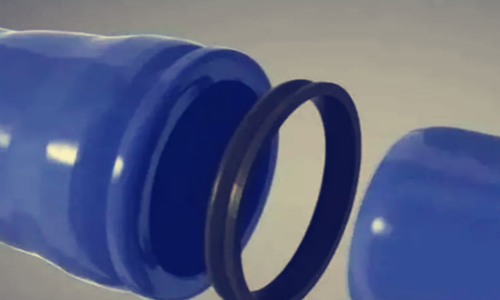

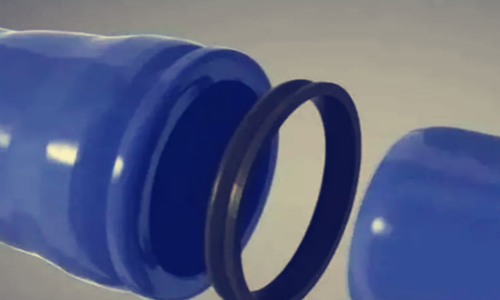

Socket connection

Before connecting the cast iron pipe, clean the sundries that affect the tightness of the socket and spigot, and put the rubber sealing ring correctly. Insert and maintain the perpendicularity of the two pipe sections according to the depth required by the construction standard.

There are relevant requirements on the connection mode of pipes in the fire water supply system. The following content is excerpted for learning.

1. The control valve on the water suction pipe of the fire pump shall be installed after the fire pump is fixed on the foundation. Its diameter shall not be less than the diameter of the water suction port of the fire pump, and the control valve without reliable locking device shall not be used, and the control valve shall be ditch type or flange type.

2. The water inlet and outlet pipes of the fire pool and fire water tank made of reinforced concrete shall be provided with waterproof sleeves, the water inlet and outlet pipes of the fire pool and fire water tank made of steel plates shall be connected with flanges, and the pipes with vibration shall be provided with flexible joints. The inlet pipe and outlet pipe joints of the combined fire water tank or fire water tank should be connected by flange, and rust proof treatment should be done when other connections are used.

3. The connection of steel plastic transition joint of steel mesh framework plastic composite pipe shall meet the following requirements:

1) The steel wire mesh framework plastic composite pipe end of the steel plastic transition joint shall be connected with the polyethylene pipe in accordance with the provisions of hot-melt connection or electric fusion connection.

2) The steel pipe end of the steel plastic transition joint and the metal pipe shall be connected in accordance with the corresponding steel pipe welding, flange connection or mechanical connection regulations.

3) The steel pipe end of the steel plastic transition joint and the steel pipe shall be connected by flange instead of welding. When welding is necessary, cooling measures shall be taken.

4. The connection mode and foundation buttress of buried pipeline shall meet the following requirements:

1) Socket connection should be used when ductile iron is used.

2) When welded steel pipe is used, flange and groove connector should be used for connection.

3) When the steel wire frame plastic composite pipe is used, the electric fusion connection shall be adopted.

5. The overhead pipeline shall be hot-dip galvanized steel pipe, and shall be connected by groove connector, thread, flange and clamping; the overhead pipeline shall not be installed with non-metallic pipeline such as steel wire frame plastic composite pipe.

6. When the pipeline is connected by means of thread, flange, socket, compression, etc., the following requirements shall be met:

1) When threaded connection is adopted, the pipe fittings of hot-dip galvanized steel pipes should adopt the relevant provisions of the current national standards GB 3287, GB 3288, GB 3289. The pipe fittings of hot-dip galvanized seamless steel pipes should adopt the current national standard GB / T 14626;

2) The thread shall conform to the relevant provisions of the current national standard 55 ° sealing pipe thread part 2: taper internal thread and taper external thread (GB 7306.2). The sealing tape shall be used as the sealing of the thread interface, and the sealing tape shall be applied on the male thread;

3) During flange connection, the sealing surface form and pressure grade of the flange shall conform to the technical requirements of the fire water supply system; the flange type shall adopt flat welding flange, butt welding flange and threaded flange according to the connection form, and the flange selection shall conform to the current national standard type and parameters of steel pipe flange GB 9112 and integral steel pipe flange GB / T 9113. Relevant provisions of steel butt welded seamless pipe fittings (GB / T 12459) and PTFE gasket for pipe flange (GB / T 13404);

4) When the hot-dip galvanized steel pipe adopts the flange connection, the threaded flange shall be selected. When it is necessary to weld the connection, the flange welding shall comply with the relevant provisions of the current national standards, code for construction of field equipment and industrial pipeline welding engineering (GB 50236) and code for construction of industrial metal pipeline engineering (GB 50235);

5) The socket connection of ductile iron pipe shall comply with the relevant provisions of the current national standard code for construction and acceptance of water supply and drainage pipeline engineering (GB 50268);

6) In addition to the relevant provisions of this specification, the construction and installation of the steel wire mesh skeleton plastic composite pipe shall also comply with the relevant provisions of the current industry standard CJJ 101 technical code for buried polyethylene water supply pipeline engineering.

7) Threaded union shall not be used for pipes with pipe diameter larger than DN50, and single reducer shall be used for pipe reducing.

Steel pipe and pipeline connection is a very important part of the project construction, directly related to the quality of the project. With the rapid development of pipeline industry, there are more and more methods to connect the pipeline. In this paper, 6 kinds of connection methods are sorted out for reference.

Threaded connection

1. Thread processing

It shall be cut in 2-3 times, and the thread shall be clear, complete and smooth without burr and disordered wire. If there is any broken or missing thread, it shall not be greater than 10% of the total thread thread number. The thread shall also meet the requirements of assembly tolerance, with a taper of 1 / 16, to prevent too loose or too tight fit between threads.

GB / t7306, 55 ° sealing pipe thread, is applicable to the threaded connection of pipes, valves, pipe joints, cocks and other pipe accessories.

2. Thread assembly

After tightening, 2-3 thread tails shall be exposed, excess packing shall be removed, and exposed thread teeth shall be painted with red lead for rust prevention. The painting width of red lead is the same, and the coating is uniform without flowing or missing.

3. Common problems

The hemp thread is not cleaned, the exposed thread is long, the painting is standard, and the painting is free of rust

Flange connection

1. Pipe flange

1) The specification and model of companion flange are the same; when connecting with equipment flange, it shall be matched according to its specification;

2) When the flange is connected, it is coaxial and parallel, and the flange surface is perpendicular to the pipe center;

3) The specification of the fastening bolt is the same, the direction is the same, the exposed length of the bolt is 1 / 2 of the bolt diameter or flush with the nut;

4) When connecting the valve, the nut shall be placed on the valve side;

5) The top two screw holes of the horizontal pipe flange shall be kept horizontal, and the two screw holes of the vertical pipe flange against the wall shall be parallel to the wall.

Flange standard: national standard gb9112-9123, Ministry of machinery standard jb79-86, Ministry of chemical industry standard hg5008-5028 and Ministry of petroleum industry standard syj4, the flange bolt hole center is the same, the pipe diameter of JB standard and Hg standard is "small outer diameter", GB standard and SYJ standard are "large outer diameter", when using, it should be noted that the number of bolt holes of individual specification flange is different.

2. Common problems

Inner ring of flange is not welded, inner ring of flange is not welded, flange does not match

Welded connection

1. Welding

1) The welding of stainless steel pipe is protected by argon filling. After welding, the weld and heat affected zone are pickled and passivated.

2) The brazing of copper pipe shall not be over heated (650-750 ℃), and the residual slag and other sundries at the welding joint shall be removed after welding.

3) No undercut, slag inclusion, crack, splash and other defects are found in the weld appearance inspection.

2. Common problems

The brazed joint of copper pipe is not cleaned, the undercut of stainless steel pipe is not treated, the width of weld is narrow, and the reinforcement is different

Groove connection

1. Groove assembly

1) Clean the pipe end, put on the rubber sealing ring, install the clamp and fasten the bolt;

2) The center line of the pipe at the two ends of the trench is the same, and the installation direction (fastening bolt position) of the trench is the same;

3) The straight pipe section should adopt rigid joint, and a flexible joint should be set between every 4-5 continuous rigid joints on the pipe section.

2. Common problems

The direction of groove joint is not uniform, and the pipes at both ends of groove are not straight.

Compression connection

Clean the insertion port and mark the insertion depth. Insert the pipe to the specified depth and keep the axis vertical. Use the special clamping tool to clamp the joint, and use the gauge to check whether the clamping dimension is in place after clamping.

Socket connection

Before connecting the cast iron pipe, clean the sundries that affect the tightness of the socket and spigot, and put the rubber sealing ring correctly. Insert and maintain the perpendicularity of the two pipe sections according to the depth required by the construction standard.

There are relevant requirements on the connection mode of pipes in the fire water supply system. The following content is excerpted for learning.

1. The control valve on the water suction pipe of the fire pump shall be installed after the fire pump is fixed on the foundation. Its diameter shall not be less than the diameter of the water suction port of the fire pump, and the control valve without reliable locking device shall not be used, and the control valve shall be ditch type or flange type.

2. The water inlet and outlet pipes of the fire pool and fire water tank made of reinforced concrete shall be provided with waterproof sleeves, the water inlet and outlet pipes of the fire pool and fire water tank made of steel plates shall be connected with flanges, and the pipes with vibration shall be provided with flexible joints. The inlet pipe and outlet pipe joints of the combined fire water tank or fire water tank should be connected by flange, and rust proof treatment should be done when other connections are used.

3. The connection of steel plastic transition joint of steel mesh framework plastic composite pipe shall meet the following requirements:

1) The steel wire mesh framework plastic composite pipe end of the steel plastic transition joint shall be connected with the polyethylene pipe in accordance with the provisions of hot-melt connection or electric fusion connection.

2) The steel pipe end of the steel plastic transition joint and the metal pipe shall be connected in accordance with the corresponding steel pipe welding, flange connection or mechanical connection regulations.

3) The steel pipe end of the steel plastic transition joint and the steel pipe shall be connected by flange instead of welding. When welding is necessary, cooling measures shall be taken.

4. The connection mode and foundation buttress of buried pipeline shall meet the following requirements:

1) Socket connection should be used when ductile iron is used.

2) When welded steel pipe is used, flange and groove connector should be used for connection.

3) When the steel wire frame plastic composite pipe is used, the electric fusion connection shall be adopted.

5. The overhead pipeline shall be hot-dip galvanized steel pipe, and shall be connected by groove connector, thread, flange and clamping; the overhead pipeline shall not be installed with non-metallic pipeline such as steel wire frame plastic composite pipe.

6. When the pipeline is connected by means of thread, flange, socket, compression, etc., the following requirements shall be met:

1) When threaded connection is adopted, the pipe fittings of hot-dip galvanized steel pipes should adopt the relevant provisions of the current national standards GB 3287, GB 3288, GB 3289. The pipe fittings of hot-dip galvanized seamless steel pipes should adopt the current national standard GB / T 14626;

2) The thread shall conform to the relevant provisions of the current national standard 55 ° sealing pipe thread part 2: taper internal thread and taper external thread (GB 7306.2). The sealing tape shall be used as the sealing of the thread interface, and the sealing tape shall be applied on the male thread;

3) During flange connection, the sealing surface form and pressure grade of the flange shall conform to the technical requirements of the fire water supply system; the flange type shall adopt flat welding flange, butt welding flange and threaded flange according to the connection form, and the flange selection shall conform to the current national standard type and parameters of steel pipe flange GB 9112 and integral steel pipe flange GB / T 9113. Relevant provisions of steel butt welded seamless pipe fittings (GB / T 12459) and PTFE gasket for pipe flange (GB / T 13404);

4) When the hot-dip galvanized steel pipe adopts the flange connection, the threaded flange shall be selected. When it is necessary to weld the connection, the flange welding shall comply with the relevant provisions of the current national standards, code for construction of field equipment and industrial pipeline welding engineering (GB 50236) and code for construction of industrial metal pipeline engineering (GB 50235);

5) The socket connection of ductile iron pipe shall comply with the relevant provisions of the current national standard code for construction and acceptance of water supply and drainage pipeline engineering (GB 50268);

6) In addition to the relevant provisions of this specification, the construction and installation of the steel wire mesh skeleton plastic composite pipe shall also comply with the relevant provisions of the current industry standard CJJ 101 technical code for buried polyethylene water supply pipeline engineering.

7) Threaded union shall not be used for pipes with pipe diameter larger than DN50, and single reducer shall be used for pipe reducing.