Plastic spray flange

Plastic spray flange

Plastic spray flange is also called electrostatic spraying flange. When working, the plastic particles are connected to the negative electrode, and the flange is connected to the positive electrode and grounded. Under the action of the high voltage of the high voltage power supply, the particles are sprayed out by the nozzle. These negatively charged particles are melted by the electrostatic field and strongly attracted by the flange, and deposited on the flange surface to form a uniform coating film.

Plastic sprayed flange is to spray plastic the flange to achieve the effect of beautiful appearance, anti-corrosion and anti-rust, and can be used in various occasions that require pipeline connection.

Application

Plastic spray flanges are mainly used in many fields such as offshore oil transportation, seawater desalination engineering, natural gas transportation, drinking water transportation, aerospace, shipbuilding, automobile manufacturing, medicine, food, sanitation, and key projects at home and abroad.

[Product Alias]: spray flange

[Connector specifications]: DN20--DN4000

[Connector color]: blue silver gray green

[Scope of use]: [Acid, alkali, seawater, oil, hot water, etc.]

[Product Certification]: [International ISO9001-2008]

[Executive standard]: CJ / T208-2005 GB / T26121-2010

[Flange Standard]: GB / T9115.1-2000 GB / T9119-2010

[Production standard]: American standard Japanese standard British standard Korean standard

[Connector material]: carbon steel stainless steel

[Working temperature]: -20- + 120

[Blasting pressure]: 3 times the working pressure

Flange

Flange is the part that connects the pipe and the pipe to each other. It is used for the connection between the pipe ends. It is also useful for the flange on the inlet and outlet of the equipment. It is used for the connection between the two equipment, such as the reducer flange. Flange connection or flange joint refers to the detachable connection of flange, gasket and bolt as a group of combined sealing structure. Pipe flange refers to the flange used for piping in the pipeline installation, and refers to the inlet and outlet flange of the equipment used in the equipment. There are holes in the flange, and the bolts tightly connect the two flanges. The flanges are sealed with gaskets. Flange is divided into threaded connection (screw connection) flange, welding flange and clip flange. Flanges are used in pairs, low-pressure pipes can use wire flanges, welding flanges for pressures above 4 kg. Add a gasket between the two flanges, and then tighten with bolts. Flanges of different pressures have different thicknesses, and they use different bolts. When the pump and valve are connected to the pipeline, some parts of these equipments are also made into corresponding flange shapes, also called flange connection. All the connecting parts that are connected by bolts and closed at the periphery of two planes are generally called flanges, such as the connection of ventilation pipes. But this connection is only a part of the equipment, such as the connection between the flange and the water pump, so it is not easy to call the water pump flange parts. Relatively small, such as valves, can be called flange parts.

Features

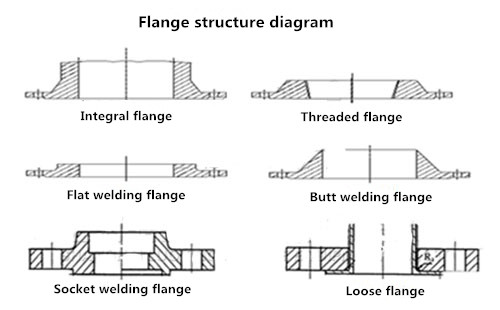

1. According to the chemical (HG) industry standards: integral flange (IF), threaded flange (Th), plate flat welding flange (PL), butt welding flange with neck (WN), flat welding flange with neck (SO), socket welding flange (SW), butt welding ring loose sleeve flange (PJ / SE), flat welding ring loose sleeve flange (PJ / RJ), lining flange cover (BL (S)), Flange cover (BL).

2. According to petrochemical (SH) industry standards: threaded flange (PT), butt welding flange (WN), flat welding flange (SO), socket welding flange (SW), loose sleeve flange (LJ) , Flange cover (not shown).

3. According to the mechanical (JB) industry standard: integral flange, butt welding flange, plate flat welding flange, butt welding ring plate loose sleeve flange, flat weld ring plate loose sleeve flange, flanging ring plate loose sleeve Flange, flange cover.

4. According to (GB) standard: integral flange, threaded flange, butt welding flange, flat welding flange with neck, socket welding flange with neck, butt welding ring with neck loose sleeve flange, flat plate welding Flange, butt welding ring plate loose sleeve flange, flat welding ring plate loose sleeve flange, flange ring plate loose sleeve flange, flange cover.

Flange structure diagram

Material

| Part | Material |

| Flange | Cast and forged carbon steel(Q235)、 Stainless steel(201、304、316、321)、Plastic(CPVC、PVDF、PPH、UPVC、RPP) |