Petroleum expansion pipe

Petroleum expansion pipe

With the oil exploitation in the middle and late stages of the oil field, oil wells often suffer from damage during the production process. The development of expandable tube technology has played a certain role in solving this series of problems.

At present, the expansion tube has been successfully applied in the ocean, saving a lot of raw materials. The use of expandable tube technology to complete the well can greatly increase the output of the oil well and reduce the cost of drilling and completion. Therefore, many major oil companies have invested manpower and financial resources in the research of expansion tube technology. And the application of this technology in the petroleum industry will become wider and wider.

Technology

Drive the vertebral body hydraulically or mechanically to increase the diameter of the expansion tube. Expansion pipe system engineering technology includes: expansion pipe materials, supporting tools and construction technology.

Performance

The pipe has high strength, high elongation, and low resilience performance; the supporting expansion tools and expansion process, and various performance indicators of the expanded pipe (including external pressure, internal pressure, suspension, and sealing) meet the needs of oilfield applications.

Classification

Physical expansion pipe: used for oil well subsidies, expansion pipe hangers, and open hole liner suspension.

Slotted expansion pipe: It is made by slitting a solid expansion pipe, which is mainly used for expansion sand control screens and expansion support nets.

Common petroleum expansion pipes include stainless steel seamless expansion pipe materials and dual-zone steel ERW expansion pipe series materials; the developed ZP series expansion pipes can meet the needs of different users. The ZP05-06 stainless steel series not only has high strength and high plasticity, but also Good corrosion resistance; ZP08-10 dual-zone steel ERW steel pipe has excellent mechanical properties and is suitable for different well conditions. ,

Expansion pipe casing subsidy

Product use: Used for repairing damaged casing wells, plugging blastholes, water layers, and repairing long well sections, strengthening long well sections and repairing misplaced wells.

Product features: Suspension force after expansion>60+, resistance to internal pressure>60Mpa, external pressure>25Mpa; expansion cone intelligent swing, anti-obstacle card; launch base pressure resistance higher than 60Mpa.

Expansion tube hanger

Product introduction: The liner hanger is made of expansion pipe string, which can ensure the seal of the liner and the upper casing.

Product use: Used in open-hole wells, only the liner suspension of various completions such as side drilling, deepening wells, and drilling can be blamed.

Product features: simple construction, using hydraulic push-up-pull combination method, the top pipe position can be adjusted and compressed according to the position of the expansion pipe, and the operation is flexible and convenient. The suspension is firm, the suspension force is >60+, and the service life is long.

Expanded sand control screen

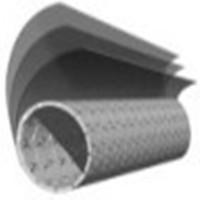

Product introduction: The expansion sand control pipe is composed of multiple layers, and the size of the gap can be designed according to the sand grain condition of the formation.

Product use: used for horizontal wells, oil production and sand control.

Product features: It can prevent sand particles above 0.07mm, the slotted pipe can expand by 20%, and the inner diameter is large

Product specification: used for sand control of 5 1/2 ", 7" casing or as tail pipe of oil and gas production layer

Expansion connector for branch well

Product introduction: Expansion pipes are prefabricated on the ground with branch connectors, which are formed by directional bifurcation after going down the well. It is one of the necessary tools for branch wells.

Product use: Used for the connection and suspension of branch wells, sidetracking wells and other branch wells.

Product features: The structure basically reaches the 6S type, with sufficient mechanical support, strong sealing, suspension bearing capacity>30+, branch pipe resistance to internal pressure>25Mpa

Product structure: It is formed by hot rolling and welding of two expansion tubes after multiple deformations, and the branch angle is 3° or 3.5° The upper connection is suspended with the main casing through expansion, and the branch casing is suspended after the lower branches are respectively expanded. After going down the well, under the action of hydraulic pressure and weight on bit, it tends to diverge naturally.

Expansion support tube

Product introduction: After the expansion pipe is run into the well, the expansion support is expanded to form a network structure, and the fiber drilling fluid is used to stabilize the wellbore and ensure the smooth progress of the drilling.

Scope of application: Suitable for support and reinforcement of well sections that are easy to collapse (such as quicksand layer, salt rock layer, gypsum layer)