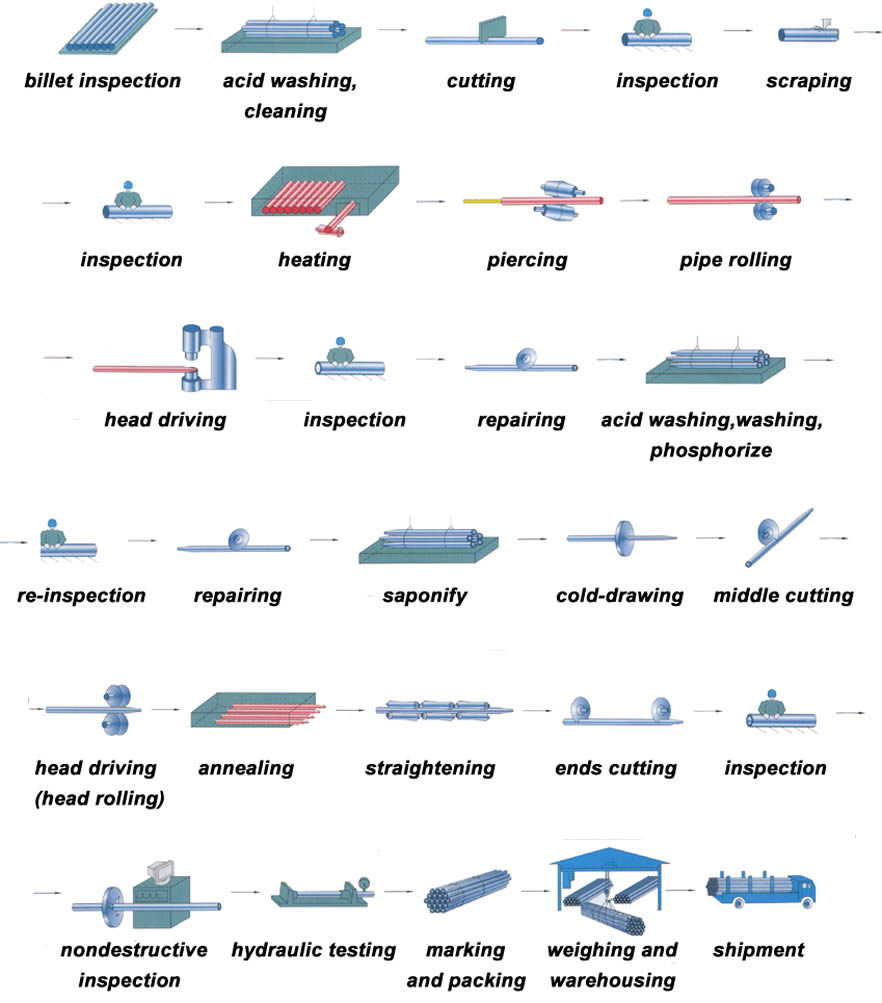

Cold drawn (rolled) seamless steel pipe process

Cold drawn

Cold drawn usually adopts longitudinal rolling. The cold rolling production process generally includes raw material preparation, pickling, rolling, degreasing, annealing (heat treatment), finishing, and the like.

Cold-rolled seamless steel tubes use hot-rolled steel tubes as raw materials, and the raw materials must be dephosphorized prior to cold rolling to ensure that the surface of the cold-rolled products is clean.

Cold drawn seamless steel pipe manufacturing process

Round tube → heating → perforation → Heading → annealing → pickling → oiled (copper) → multi-pass cold drawn (cold rolled) → blank tube → heat treatment → straightening →hydrostatic testing (testing) → Mark → storage.

Rolling is the main process to deform the steel tube. The purpose of degreasing is to remove the lubricating grease attached to the steel pipe during rolling so as not to contaminate the surface of the steel pipe during annealing, and to prevent carbonation of the stainless steel pipe. Annealing includes intermediate annealing and finished heat treatment. Intermediate annealing eliminates work hardening caused by cold deformation by recrystallization to restore the plasticity of the steel tube and reduce the deformation resistance of the metal. The purpose of the finished heat treatment is to eliminate hardening by recrystallization. It is also based on the technical requirements of the seamless steel pipe to obtain the desired structure (such as various textures, etc.) and the performance of the steel pipe (such as deep drawing, electromagnetic properties, etc.). Finishing includes inspection, cutting, straightening (leveling), printing, sorting and packaging. Cold-rolled products have high packaging requirements to prevent the surface of products from being scratched during transportation.

In addition to the above processes, there are special processes for producing some special products. For example, when rolling silicon steel plates, decarburization annealing is carried out before cold rolling. After rolling, coating film, high temperature annealing, tension straightening (see tension straightening) and tempering, etc. should be performed.

Features of cold drawn seamless steel pipe

The wall thickness of cold-rolled seamless steel tubes is generally smaller than that of hot-rolled seamless steel tubes. But the surface looks brighter than a thick-walled seamless steel tube. The surface is not too rough, there are not many burrs in the caliber.The maximum nominal diameter of the cold rolled tube is 200 mm, and the maximum nominal diameter of the hot rolled tube is 600 mm.

The main advantage of cold-rolled steel pipes is the large reduction in section, especially the ability to reduce wall thickness. For carbon steel, the reduction rate of one-step rolling section can reach 80% to 83%, and that of alloy steel can reach 72% to 75%. Its main drawback is the difficulty of tool replacement. The cold rolling method is often used in combination with a cold drawing method in addition to directly producing a part of a cold rolling tube with high precision, and is a cold drawing blank. In this way, the ability to reduce cold-rolling capacity can be fully utilized, and the advantages of easy-to-replace cold-drawing tools can also be used skillfully to increase productivity, expand product range, and improve surface quality of steel pipes.