JIS G3459 Stainless Steel Pipes

JIS G3459 Stainless Steel Pipes

Standard:JIS G3459

Scope

The Japanese Industrial Standard specifies the stainless steel pipes (hereafter referred tp as "pipes") used for the pipings for corrosion resistance, low temperature sevice, high temperature service, etc.

Grades of JIS G3459 Stainless Steel Pipes

Pipes shall be classified into 29 grades, SUS304、SUS304H、SUS304L、SUS309、SUS309S、SUS310、SUS310S、SU316、SUS316H、SUS316L、SUS316Ti、SUS317、SUS317L、SUS836L、SUS890L、SUS321、SUS321H、SUS347、SUS347H、SUS329J1、SUS 329J3L、SUS329J4L、SUS405、SUS409L、SUS430、SUS430LX、SUS430J1L、SUS436L、SUS444

Method of manufacture

Pipes shall be manufactured by a seamless process, an automatic arc welding process, a laser welding process, or an electric resistance welding process.

Heat treatment

| Classification | Grade | Solution treatment ℃ |

| Austenitic pipes | SUS 304TP | 1010 min, rapid cooling |

| SUS 304HTP | 1040 min, rapid cooling | |

| SUS 304LTP | 1010 min, rapid cooling | |

| SUS 309TP | 1030 min, rapid cooling | |

| SUS 309STP | 1030 min, rapid cooling | |

| SUS 310TP | 1030 min, rapid cooling | |

| SUS 310STP | 1030 min, rapid cooling | |

| SUS 316TP | 1010 min, rapid cooling | |

| SUS 316HTP | 1040 min, rapid cooling | |

| SUS 316LTP | 1010 min, rapid cooling | |

| SUS 316TiTP | 920 min, rapid cooling | |

| SUS 317TP | 1010 min, rapid cooling | |

| SUS 317LTP | 1010 min, rapid cooling | |

| SUS 836LTP | 1030 min, rapid cooling | |

| SUS 890LTP | 1030 min, rapid cooling | |

| SUS 321TP | 920 min, rapid cooling | |

| SUS 321HTP |

Cold-finished 1095 min, rapid cooling Hot-finished 1050 min, rapid cooling |

|

| SUS 347TP | 980 min, rapid cooling | |

| SUS 347HTP |

Cold-finished 1095 min, rapid cooling Hot-finished 1050 min, rapid cooling |

|

| Austenitic-ferritic pipes | SUS 329J1TP | 950 min, rapid cooling |

| SUS 329J3LTP | 950 min, rapid cooling | |

| SUS 329J4LTP | 950 min, rapid cooling | |

| Ferritic pipes | SUS 405TP | Annealing 700 min, air cooling or slow cooling |

| SUS 409LTP | Annealing 700 min, air cooling or slow cooling | |

| SUS 430TP | Annealing 700 min, air cooling or slow cooling | |

| SUS 430LXTP | Annealing 700 min, air cooling or slow cooling | |

| SUS 430J1LTPP | Annealing 720 min, air cooling or slow cooling | |

| SUS 436LTPTP | Annealing 720 min, air cooling or slow cooling | |

| SUS 444TP | Annealing 700 min, air cooling or slow cooling |

Remarks

For the pipes of SUS321TP, SUS316TiTP and SUS347TP, stabilizing treatment may be specified. In this case, the temperature of heat treatment shall be from 850n to n.

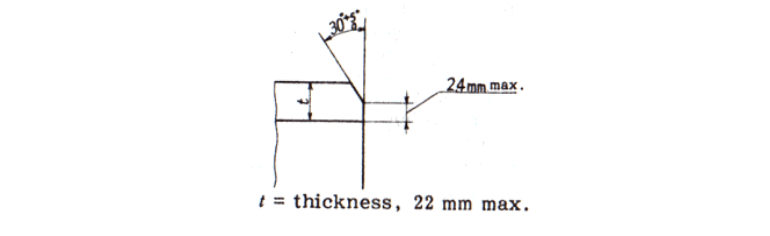

When required by the purchaser, the pipes may be fabricated to the bevel end (1)

Note (1) Unless otherwise specified, the shape of the bevel end shall be as given in Fig. 1.

Chemical composition

| Grades | Chemical composition | ||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Others | |

| SUS 304 TP | 0.08 max. | 1.00 max. | 2.00max. | 0.040 max. | 0.030 max. | 8.00~11.00 | 18.00~20.00 | -- | -- |

| SUS 304 HTP | 0.04~0.10 | 0.75max. | 2.00 max. | 0.040 max. | 0.030 max. | 8.00~11.00 | 18.00~20.00 | -- | -- |

| SUS 304 LTP | 0.030 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max. | 9.00~13.0 | 18.00~20.00 | -- | -- |

| SUS 309 TP | 0.15 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max. | 12.00~15.00 | 22.00~24.00 | -- | -- |

| SUS 309 STP | 0.08 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max. | 12.00~15.00 | 22.00~24.00 | -- | -- |

| SUS 310 TP | 0.15 max | 1.50 max. | 2.00 max. | 0.040 max. | 0.030 max | 19.00~22.00 | 24.00~26.00 | -- | -- |

| SUS 310 STP | 0.08 max. | 1.50 max. | 2.00 max. | 0.040 max. | 0.030 max. | 19.00~22.00 | 24.00~26.00 | -- | -- |

| SUS 316TP | 0.08 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max. | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | -- |

| SUS 316HTP | 0.04~0.10 | 0.75 max. | 2.00 max. | 0.030 max. | 0.030 max. | 11.00~14.00 | 16.00~18.00 | 2.00~3.00 | -- |

| SUS 316LTP | 0.030 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max. | 12.00~16.00 | 16.00~18.00 | 2.00~3.00 | -- |

| SUS 316TiTP | 0.08 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | Ti 5XC % min. |

| SUS 317TP | 0.08 max. | 1.00 max | 2.00 max. | 0.040 max. | 0.030 max. | 11.00~15.00 | 18.00~20.00 | 3.00~4.00 | -- |

| SUS 317LTP | 0.030 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max. | 11.00~15.00 | 18.00~20.00 | 3.00~4.00 | -- |

| SUS 836LTP | 0.030 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max | 24.00~26.00 | 19.00~24.00 | 5.00~7.00 | N 0.25 min. |

| SUS 890LTP | 0.020 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max. | 23.00~28.00 | 19.00~23.00 | 4.00~5.00 | Cu 1.00~2.00 |

| SUS 321TP | 0.08 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max. | 9.00~13.00 | 17.00~19.00 | -- | Ti 5】C% min. |

| SUS 321HTP | 0.04~0.10 | 0.75 max. | 2.00 max. | 0.030 max. | 0.030 max. | 9.00~13.00 | 17.00~20.00 | -- | Ti 4】C% ~ 0.6 |

| SUS 347TP | 0.08 max. | 1.00 max. | 2.00 max. | 0.040 max. | 0.030 max. | 9.00~13.00 | 17.00~19.00 | -- | Nb 10】C% min. |

| SUS 347HTP | 0.04~0.10 | 1.00 max. | 2.00 max. | 0.030 max. | 0.030 max. | 9.00~13.00 | 17.00~20.00 | -- | Nb 8】C% min. |

| SUS 329J1TP | 0.08 max. | 1.00 max. | 1.50 max | 0.040 max. | 0.030 max. | 3.00~6.00 | 23.00~28.00 | 1.00~3.00 | -- |

| SUS 329J3TP | 0.030 max. | 1.00 max. | 1.50 max. | 0.040 max. | 0.030 max. | 4.50~6.50 | 21.00~24.00 | 2.50~3.50 | N 0.08~0.20 |

| SUS 329J4LTP | 0.030 max. | 1.00 max. | 1.50 max. | 0.040 max. | 0.030 max. | 5.50~7.50 | 24.00~26.00 | 2.50~3.50 | N 0.08~0.30 |

| SUS 405TP | 0.08 max. | 1.00 max. | 1.00 max. | 0.040 max. | 0.030 max. | -- | 11.50~14.50 | -- | A1 0.10】0.30 |

| SUS 409LTP | 0.030 max. | 1.00 max. | 1.00 max. | 0.040 max. | 0.030 max. | -- | 10.50~11.75 | -- | Ti 6XC%~0.75 |

| SUS 430TP | 0.012 max. | 0.75 max. | 1.00 max. | 0.040 max. | 0.030 max. | -- | 16.00~18.00 | -- | -- |

| SUS 430LXTP | 0.030 max. | 0.75 max. | 1.00 max. | 0.040 max. | 0.030 max. | -- | 16.00~19.00 | -- | Ti Nb 0.10~1.00 |

| SUS 430LXTP | 0.025 max. | 1.00 max. | 1.00 max. | 0.040 max. | 0.030 max. | -- | 16.00~20.00 | -- |

N 0.025 max.

Nb 8 X (C%+N%)~8

Cu 0.30~0.80

|

| SUS 436LTP | 0.025 max. | 1.00 max. | 1.00 max. | 0.040 max. | 0.030 max. | -- | 16.00~19.00 | -- |

N 0.025 max.

Ti, Nb Zr or their combination 8X(C%+N%)~0.08 |

| SUS 444TP | 0.025 max. | 1.00 max. | 1.00 max. | 0.040 max. | 0.030 max | -- | 16.00~20.00 | -- |

N 0.025 max.

Ti Nb,Zr or their combination 8X(C%+N%)~0.08

|

Remarks

1. Even when a product analysis is required by the purchaser, the chemical composition given in Table 2 shall be applied. However, the carbon content for SUS 304 LTP, SUS 316 LTP SUS 317 LTP, SUS 836LTP, SUS 329J3LTP, SUS 329J4LTP, SUS 409LTP, SUS430LXTP shall be 0.035 % or under, The carbon content for SUS430J1LTP,SUS436LTP and SUS444TP shall be 0.030 % or under. The carbon content for SUS890LTP shall be 0.025 % or under.

2. To SUS 329 J1TP, SUS 329J3LTP, SUS 329J4LTP, alloying elements other than those given in Table may be added, if necessary.

3. SUS 405TP, SUS 430TP, SUS 430LXTP, SUS430J1LTP, SUS 436LT, SUS 444TP may contain Ni 0.60 % or under.

Mechanical properties

|

Grade

|

Mechanical properties | |||||

| Tensile strength | Yield Strength | Elongation % | ||||

| kgf/mm 2 {N/mm2} | kgf/mm 2 {N/mm2} |

No. 11 test piece

No. 12 test piece

|

No.5 test piece | No.4 test piece | ||

| Longitudinal direction | Transverse direction | Longitudinal direction | Transverse direction | |||

| SUS 304 TP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 304 HTP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 304 LTP | 49{481}min. | 18{177} min | 35 min | 25 min | 30 min | 22 min |

| SUS 309 TP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 309 STP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 310 TP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 310 STP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 316TP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 316HTP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 316LTP | 49{481}min. | 18{177} min | 35 min | 25 min | 30 min | 22 min |

| SUS 316TiTP | 53{520}min. | 21{206} min | 35 min | 25 min | 130 min | 22 min |

| SUS 317TP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 317LTP | 49{481}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 836LTP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 890LTP | 49{481}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 321TP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 321HTP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 347TP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 347HTP | 53{520}min. | 21{206} min | 35 min | 25 min | 30 min | 22 min |

| SUS 329J1TP | 60{588}min. | 40{392} min | 18 min | 13 min | 14 min | 10 min |

| SUS 329J3TP | 63{618}min. | 46{451} min | 18 min | 13 min | 14 min | 10 min |

| SUS 329J4LTP | 42{412}min. | 21{206} min | 20 min | 14 min | 14 min | 10 min |

| SUS 405TP | 42{412}min. | 21{206} min | 20 min | 14 min | 16 min | 11 min |

| SUS 409LTP | 360 min | 175 min | 20 min | 14 min | 16 min | 11 min |

| SUS 430TP | 410 min | 245 min | 20 min | 14 min | 16 min | 11 min |

| SUS 430LXTP | 360 min | 175 min | 20 min | 14 min | 16 min | 11 min |

| SUS 430LXTP | 390 min | 205 min | 20 min | 14 min | 16 min | 11 min |

| SUS 436LTP | 410 min | 245 min | 20 min | 14 min | 16 min | 11 min |

| SUS 444TP | 410 min | 245 min | 20 min | 14 min | 16 min | 11 min |

Remarks

1. When a tensile test is carried out with No. 12 or No. 5 test piece for pipes of under 8mm in wall thickness, the minimum elongation shall be calculated by subtracting 1.5 % from the elongation given in Table 4 for each decrease of 1mm from 8mm in wall thickness, and rounded off to an integer in accordance with JIS Z 8401. Examples of calculation are given in Informative reference Table.

2. The elongation given in Table shall not be applied to pipes of under 40mm in outside diameter. However, the value of elongation shall be recorded.

3. In the case where a tensile test piece is taken from automatic arc welded pipes, laser welded pipes, or electric resistance welded pipes, No. 12 or No. 5 test piece shall be taken from the portion having no welded seams.

Appearance

Pipes shall be straight for practical purposes, and their both ends shall be at right angles to the axis.

The inside and outside surfaces of the pipes shall be well finished, and free from defects detrimental to practical use.

Dimensional tolerances

The tolerances on outside diameter, wall thickness, and eccentricity of pipe

Tolerances on outside diameter, wall thickness and eccentricity

| Division | Tolerances on outside diameter | Tolerances on wall thickness | Tolerances on eccentricity |

| ot-finished seamless pipe | Under 50mm 【0.5mm | Under 4mm 【0.5mm |

At most 20 % of wall

thickness

|

| 50mm or over 【1% | 4mm or over 【12.5% | ||

|

Cold-finished seamless pipe, automatic arc welded pipe,

electric resistance welded pipe, and laser welded pipe

|

Under 30mm 【0.3mm | Under 2mm 【0.2mm | --- |

| 30mm or over 【1% | 2mm or over 【10% |

Remarks

The eccentricity means the ratio of the difference between maximum and minimum wall thickness measured in the same section to the specified wall thickness, and this shall not be applied to pipes under 5.6mm in wall thickness..

As for the portions locally ground or the like, the above tolerance on outside diameter shall not be applied if it is confirmed that the wall thickness is within the tolerance range given in the above table.

Tests

Chemical analysis

General matters common to chemical analysis and the method of sampling specimens form analysis shall be in accordance with 3. in JIS G 0303.

Analytical method the analytical method shall be in accordance with any one of the following standards

JIS G 1211, JIS G 1212, JIS G 1213, JIS G 1214, JIS G 1215, JIS G 1216,JIS G 1217, JIS G 1218, JIS G 1223, JIS G 1224, JIS G 1237, JIS G 1253,JIS G 1256, JIS G 1257

Tensile test

Test piece

The test piece shall be any one of No.11, No. 12A, No. 12B, No.12C, No.4 or No. 5 specified in JIS Z 2201 to be cut off from the pipe. IN the case of No. 4 test piece, the gauge length shall be 50mm.

Test method

The test method shall be in accordance with JIS Z 2241

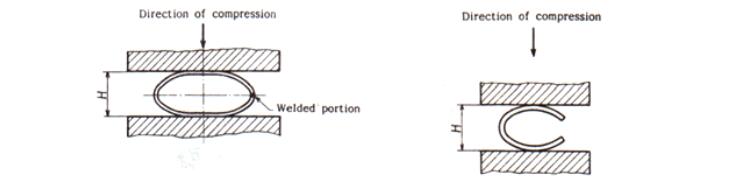

Flattening test

Test piece

A length 50mm or over of a pipe shall be cut off from the end of the pipe to serve as a test piece. For the pipe whose wall thickness is 15 % or over of the outside diameter, a C-shape test piece made by removing a part of the circumference of a ring-shaped test piece may be used.

Test method

Place the test piece at ordinary temperature between two flat plates and flatten by compression until the distance between the flat plates reaches the specified value, and examine for the occurrence of flaws or cracks on the wall surface of the test piece. In the cases of the automatic arc welded pipe, laser welded pipe, and electric resistance welded pipe,the weld zone shall be placed at right angles to the direction of compression as shown in Fig 2, and the C-shape test piece shall be placed as shown in Fig. 3.

Austenitic grain size test

Test piece

A 20mm long pipe shall be cut off from the pipe end to serve as a test piece..

Test method

The austenitic grain size number shall be measured in accordance with JIS G 0551.

Hydraulic test or nondestructive examination

Hydraulic test

When the pipe is subjected to a hydraulic pressure and kept at the specified pressure for 5 s or longer, whether it withstands the pressure without leakage shall be examined.

Nondestructive examination

The test method of a nondestructive examination shall be in accordance with JIS G 0582, JIS G 0583 or JIS Z 3106.

Marking

Each pipe having passed the inspection shall be marked with the following items. However, in the case of either small pipes or a requirement from the purchaser, the pipes may be bundled and marked for each bundle by a suitable means. In either case, the order of arranging the items is not specified.

When approved by the purchaser, a part of the items may be omitted.

(1) Symbol of grade

(2) Symbol indicating the manufacturing method ( 3 )

(3) Dimension ( 4 )

(4) Manufacturer’s name or abbreviation

(5) Symbol Z indicating the special quality requirement

Note ( 3 )

The symbols indicating the manufacturing method shall be as follows. However, the sign of dash may be replaced by a space.

Hot-finished seamless pipe -S-H

Cold-finished seamless pipe -S-C

Automatic arc welded pipe -A

Cold-finished automatic arc welded pipe -A-C

Weld zone work finished automatic arc welded pipe -A-B

Laser welded pipe -L

Cold-finished laser welded pipe -L-D

Weld zone work finished laser welded pipe -L-B

Electric resistance welded pipe other than hot-finished or cold finished ones -E-G

Cold-finished electric resistance welded pipe -E-C

Note ( 4 )

The dimensions shall be indicated as follows

Nominal diameter X nominal wall thickness, outside diameter X wall thickness or nominal diameter X wall thickness

Example : 50A × Sch 10S