GB/T 20409 Multi-rifled Steel Pipe For High-pressure Boiler

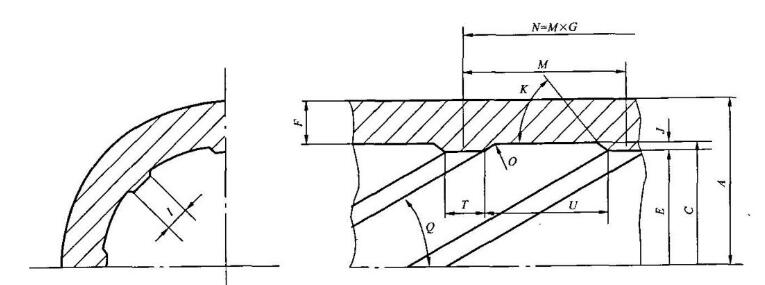

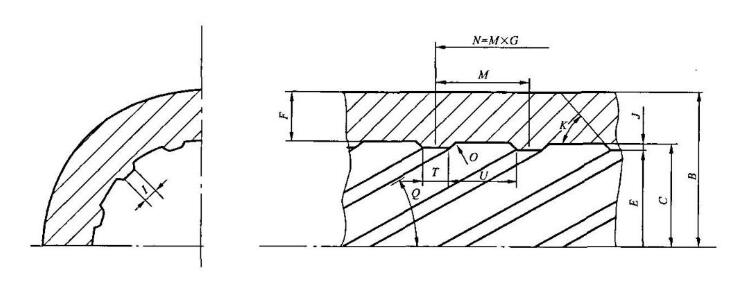

Q - Thread Increase Angle.

U - thread top (axial) slot width.

"A" Multi-Rifled pipe with teeth and thread parameters shall conform to Table 1, while "B" Multi-Rifled pipe with teeth shall conform to Table 2.

Table 1 Dimensions and thread parameters of "A" type Multi-Rifled pipe

|

Nominal |

Thread |

The |

Nominal |

Minimum |

Number of thread heads |

Thread Top Width (Circumference) /mm |

Thread height |

Thread Side Angle |

Radius of rounded corner at the root of thread |

Thread pitch, |

Thread Lead |

Thread Increase Angle |

Thread top width (axial) |

Thread top (axial) slot width |

|

A |

C |

E |

S |

F |

G |

I |

J |

K |

O |

M |

N |

Q |

T |

U |

|

28.6 |

15.84 |

13.39 |

6.38 |

5.8 |

4 |

4.78 |

0.85 |

55。 |

0.13~1.27 |

21.55 |

86.19 |

30。 |

8.28 |

13.27 |

|

44.5 |

33.18 |

30.34 |

5.66 |

5.1 |

6 |

1.01 |

30.08 |

180.49 |

21.80 |

|||||

|

45 |

33 |

30.20 |

6 |

5.4 |

6 |

1.01 |

30 |

180 |

21.70 |

|||||

|

50.8 |

37.92 |

34.93 |

6.44 |

5.8 |

8 |

1.06 |

25.79 |

206.29 |

17.51 |

|||||

|

51 |

38.35 |

35.35 |

6.33 |

5.7 |

8 |

1.10 |

26.10 |

208.80 |

17.80 |

|||||

|

60 |

46 |

42.92 |

7 |

6.3 |

8 |

1.10 |

31.30 |

250.40 |

23 |

|||||

|

60 |

44 |

41 |

8 |

7.2 |

8 |

1.10 |

30 |

240 |

21.70 |

|||||

|

60.3 |

43.4 |

40.32 |

8.33 |

7.5 |

8 |

1.12 |

29.52 |

236.16 |

21.24 |

|||||

|

60.3 |

42.3 |

39.10 |

9 |

8.1 |

8 |

1.12 |

28.76 |

230.10 |

20.49 |

|||||

|

60.3 |

31.44 |

28.55 |

14.43 |

13 |

8 |

1.02 |

21.38 |

171.07 |

13.11 |

|||||

|

63.5 |

48.8 |

45.64 |

7.33 |

6.6 |

8 |

1.16 |

33.19 |

265.54 |

24.91 |

|||||

|

63.5 |

48.5 |

45.30 |

7.50 |

6.7 |

8 |

1.16 |

33 |

264 |

24.70 |

|||||

|

63.5 |

47.72 |

44.53 |

7.89 |

7.1 |

8 |

1.17 |

32.49 |

259.89 |

24.21 |

|||||

|

63.5 |

47.52 |

44.29 |

7.99 |

7.2 |

8 |

1.15 |

32.31 |

258.51 |

24.03 |

|||||

|

63.5 |

39.24 |

36.19 |

12.13 |

10.9 |

8 |

1.07 |

26.70 |

213.49 |

18.42 |

|||||

|

63.5 |

39.09 |

36.10 |

12.21 |

11 |

8 |

1.04 |

26.59 |

212.70 |

18.31 |

|||||

|

63.5 |

35.30 |

32.32 |

14.10 |

12.7 |

8 |

1.04 |

24 |

192 |

15.72 |

|||||

|

63.5 |

34.64 |

31.66 |

14.43 |

13 |

8 |

1.04 |

23.56 |

188.49 |

15.28 |

|||||

|

69.8 |

37.77 |

34.72 |

16.04 |

14.4 |

8 |

1.07 |

25.68 |

205.46 |

17.40 |

|||||

|

70 |

50 |

46.72 |

10 |

9 |

8 |

1.20 |

34 |

272 |

25.72 |

|||||

|

70 |

52 |

48.70 |

9 |

8.1 |

8 |

1.20 |

35.37 |

282.95 |

21.09 |

|||||

|

76.2 |

39.55 |

36.47 |

18.33 |

16.5 |

8 |

1.07 |

26.99 |

215.19 |

18.62 |

Table 2 Dimensions and thread parameters of "B" type Multi-Rifled pipe

|

Nominal Outer diameter /mm |

Thread |

The |

Nominal |

Minimum |

Number of thread heads |

Thread Top Width (Circumference) /mm |

Thread height |

Thread Side Angle |

Radius of rounded corner at the root of thread |

Thread pitch, |

Thread Lead |

Thread Increase Angle |

Thread top width (axial) |

Thread top (axial) slot width |

|

B |

C |

E |

S |

F |

G |

I |

J |

K |

O |

M |

N |

Q |

T |

U |

|

35 |

20.60 |

18.10 |

7.20 |

6.5 |

6 |

3.23 |

0.95 |

50。 |

0.4~2 |

18.67 |

112 |

30。 |

5.60 |

13.07 |

|

38 |

23.60 |

20.80 |

7.20 |

6.5 |

6 |

0.99 |

21.39 |

128.20 |

15.79 |

|||||

|

38.1 |

23.23 |

20.49 |

7.44 |

6.7 |

6 |

0.99 |

21.06 |

126.40 |

15.46 |

|||||

|

60 |

45.60 |

42.20 |

7.20 |

6.5 |

12 |

1.23 |

20.70 |

247.90 |

15.10 |

|||||

|

60 |

44.50 |

41.20 |

7.75 |

7 |

12 |

1.22 |

20.18 |

242.10 |

14.56 |

|||||

|

60 |

43.40 |

40.10 |

8.30 |

7.5 |

12 |

1.21 |

19.68 |

236.15 |

14.08 |

|||||

|

66.7 |

50.70 |

- |

8 |

7.2 |

12 |

3.83 |

1.24 |

23 |

276 |

6.64 |

16.36 |

|||

|

66.7 |

49.60 |

- |

8.55 |

7.7 |

12 |

1.24 |

22.50 |

270 |

15.86 |

| Project | Size range / mm | Type A | Type B | Type OM |

| Outer diameter | ≤38.1 | ±0.15mm | ±0.15mm | ±0.15mm |

| >38.1~<50.8 | ±0.2mm | ±0.2mm | ±0.2mm | |

| ≥50.8~<63.5 | ±0.25mm | ±0.25mm | - | |

| ≥63.5 | ±0.3mm | ±0.3mm | - | |

| Thread root diameter | ≤38.1 | ±0.15mm | ±0.15mm | ±0.15mm |

| >38.1~<50.8 | ±0.2mm | ±0.2mm | ±0.2mm | |

| ≥50.8~<63.5 | ±0.25mm | ±0.25mm | - | |

| ≥63.5 | ±0.3mm | ±0.3mm | - | |

| Minimum inner diameter | - | The lower deviation is 0 | The lower deviation is 0 | - |

| Minimum wall thickness | - |

+22% mm 0 |

+22% mm 0 |

+22% mm 0 |

| Wall thickness | - | ±10%mm | ±10%mm | ±10%mm |

| Thread height | ≤38.1 | ±0.2mm | ±0.18mm | ±0.2mm |

| >38.1~<50.8 | ±0.3mm | ±0.2mm | ±0.2mm | |

| ≥50.8~<63.5 | ±0.3mm | ±0.23mm | ±0.2mm | |

| ≥63.5 | ±0.3mm | ±0.28mm | ±0.2mm | |

| Thread side angle | - | ±15° | ±15° |

+30° -10° |

| Thread pitch | - | ±3.2mm | ±3.2mm | - |

| Thread lead | - | ±3.2mm*Number of threads | ±3.2mm*Number of threads | - |

| Thread angle | - | - | - |

+5° 0° |

| Thread top width (axial) | - | ±1.3mm | ±1.3mm | ±1.3mm |

Table 4 Chemical Composition of GB/T 20409 Multi-rifled Steel Pipe

|

Grade |

chemical composition(%) |

||||||

|

C |

Mn |

Si |

Cr |

Mo |

S |

P |

|

|

20G |

0.17~0.23 |

0.35~0.65 |

0.17~0.37 |

- |

- |

≤0.020 |

≤0.025 |

|

20MnG |

0.17~0.23 |

0.70~1.00 |

0.17~0.37 |

- |

- |

≤0.020 |

≤0.025 |

|

25MnG |

0.22~0.29 |

0.70~1.00 |

0.17~0.37 |

- |

- |

≤0.020 |

≤0.025 |

|

12CrMoG |

0.08~0.15 |

0.40~0.70 |

0.17~0.37 |

0.40~0.70 |

0.40~0.55 |

≤0.020 |

≤0.025 |

|

15CrMoG |

0.12~0.18 |

0.40~0.70 |

0.17~0.37 |

0.80~1.10 |

0.40~0.55 |

≤0.020 |

≤0.025 |

|

Note 1: The residual element content of 20G, 20MnG and 25MnG should be consistent with: Cu≤0.20%, Cr≤0.25%, Ni≤0.25%, V≤0.08%, Mo≤0.15%; the residual element content of the remaining grades should be consistent with: Cu ≤0.20%, Ni≤0.30%.

Note 2: The acid-soluble aluminum in 20G steel should be no more than 0.010%.

Note 3: The steel produced by refining with oxygen and refining should have a nitrogen content of not more than 0.008%.

|

|||||||

| Grade | Heat treatment |

| 20G | Normalizing, normalizing temperature: 880 ° C ~ 940 ° C |

| 20MnG | Normalizing, normalizing temperature: 880 ° C ~ 940 ° C |

| 25MnG | Normalizing, normalizing temperature: 880 ° C ~ 940 ° C |

| 12CrMoG | Normalizing and tempering, normalizing temperature: 900 ° C ~ 960 ° C; tempering temperature: 670 ° C ~ 730 ° C |

| 15CrMoG | Normalizing and tempering, normalizing temperature: 900 ° C ~ 960 ° C; tempering temperature: 680 ° C ~ 730 ° C |

Mechanical Properties

Table 6 Mechanical Properties

|

Grade |

Tensile strength Rm/ MPa(N/mm2) |

Yield Strength R eL/ MPa(N/mm2) |

Elongation A/% |

Impact energy Akv/J |

|

≥ |

||||

|

20G |

410~550 |

245 |

24 |

35 |

|

20MnG |

≥415 |

240 |

22 |

35 |

|

25MnG |

≥485 |

275 |

20 |

35 |

|

12CrMoG |

410~560 |

205 |

21 |

35 |

|

15CrMoG |

440~640 |

235 |

21 |

35 |