ASTM A517/ASME SA517 Specification For Steel Plate

ASTM A517/ ASME SA-517

SPECIFICATION FOR PRESSURE VESSEL PLATES, ALLOY STEEL, HIGH-STRENGTH, QUENCHED AND TEMPERED

1. Scope

1.1 This specification covers high-strength quenched and tempered alloy steel plates intended for use in fusion welded boilers and other pressure vessels.

1.2 This specification includes a number of grades as manufactured by different producers, but all having the same mechanical properties and general characteristics.

1.3 The maximum thickness of plates furnished under this specification shall be as follows:

| Grade | Thickness |

| A, B | 1.25 in. [32 mm] |

| H, S | 2 in. [50 mm] |

| P | 4 in. [100 mm] |

| F | 2.50 in. [65 mm] |

| E, Q | 6 in. [150 mm] |

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system is to be used independently of the other without combining values in any way.

2. Referenced Documents

2.1 ASTM Standards:

A 20 /A 20M Specification for General Requirements for Steel Plates for Pressure Vessels

A 435 /A 435M Specification for Straight-Beam Ultrasonic Examination of Steel Plates

A 577 /A 577M Specification for Ultrasonic Angle-Beam Examination of Steel Plates

A 578 /A 578M Specification for Straight-Beam Ultrasonic Examination of Plain and Clad Steel Plates for Special Applications

3. General Requirements and Ordering Information

3.1 Plates furnished to this material specification shall conform to Specification A 20 /A 20M. These requirements outline the testing and retesting methods and procedures, permissible variations in dimensions, and mass, quality and repair of defects, marking, loading, etc.

3.2 Specification A 20 /A 20M also establishes the rules for the ordering information which should be complied with when purchasing material to this specification.

3.3 In addition to the basic requirements of this specifi- cation, certain supplementary requirements are available when additional control, testing, or examination is required to meet end use requirements. These include:

3.3.1 Vacuum treatment,

3.3.2 Additional or special tension testing,

3.3.3 Impact testing, and

3.3.4 Nondestructive examination.

3.4 The purchaser is referred to the listed supplemen- tary requirements in this specification and to the detailed requirements in Specification A 20 /A 20M.

3.5 If the requirements of this specification are in con- flict with the requirements of Specification A 20 /A 20M, the requirements of this specification shall prevail.

4. Manufacture

4.1 Steelmaking Practice — The steel shall be killed and shall conform to the fine austenitic grain size require- ment of Specification A 20/A 20M.

5. Heat Treatment

5.1 Except as allowed by section 5.2, the plates shall be heat treated by heating to not less than 1650°F [900°C],quenching in water or oil and tempering at not less than 1150°F [620°C].

5.2 Plates ordered without the heat treatment specified in section 5.1 shall be stress relieved by the manufacturer, and subsequent heat treatment of the plates to conform to section 5.1 shall be the responsibility of the purchaser.

6. Chemical Requirements

6.1 The steel shall conform to the chemical require- ments shown in Table 1 unless otherwise modified in accor- dance with Supplementary Requirement S17, Vacuum Carbon-Deoxidized Steel, in Specification A 20 /A 20M for grades other than Grade A.

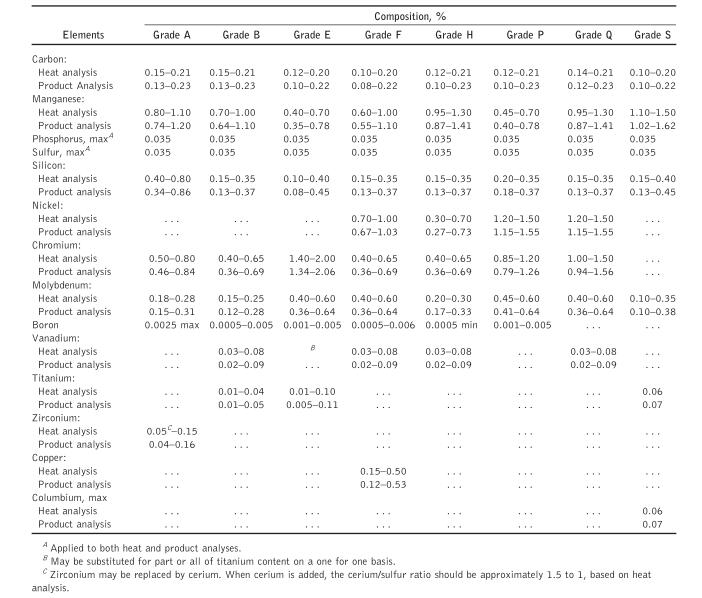

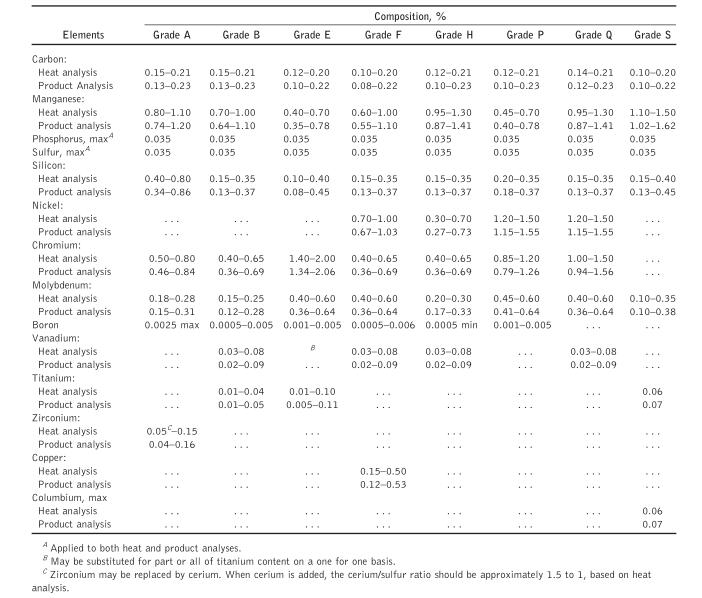

Table 1 Chemical Requirements

7. Mechanical Requirements

7.1 Tension Tests:

7.1.1 Requirements — The plates as represented by the tension-test specimens shall conform to the require- ments given in Table 2.

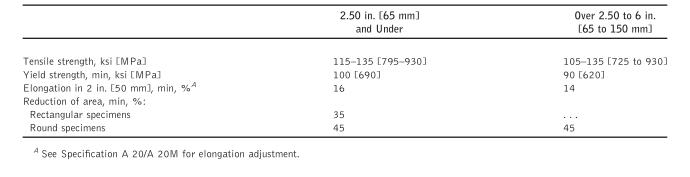

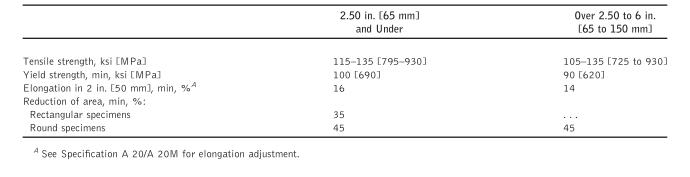

Table 2 Mechanical Requirements

7.1.2 Test Methods:

7.1.2.1 The yield strength may be determined by the 0.2% offset method or by the total extension under load of 0.5% method.

7.1.2.2 For plates 3⁄4 in. [20 mm] and under in thickness, the test specimen shall be the 1 1⁄2in. [40 mm] wide rectangular-test specimen.

7.1.2.3 For plates over 3⁄4 in. [20 mm], either the full thickness rectangular-test specimen or the 1⁄2 in. [12.5 mm] round-test specimen may be used.

7.1.2.4 When the 11⁄2 in. [40 mm] wide rectangular- test specimen is used, the elongation is measured in a 2 in. or [50 mm] gage length which includes the fracture.

7.2 Impact Properties Requirements:

7.2.1 Transverse Charpy V-notch impact test speci- mens shall have a lateral expansion opposite the notch of not less than 0.015 in. [0.38 mm].

7.2.2 The test temperature shall be agreed upon between the manufacturer and the purchaser, but shall not be higher than 32°F [0°C].

8. Keywords

8.1 alloy steel; boilers; high-strength; impact tested; plates; pressure vessels; quenched; tempered

SUPPLEMENTARY REQUIREMENTS

Supplementary requirements shall not apply unless specified in the order.

A list of standardized supplementary requirements for use at the option of the purchaser are included in Specification A 20 /A 20M. Several of those considered suitable for use with this specification are listed by title. Other tests may be performed by agreement between the supplier and the purchaser.

S1. Vacuum Treatment,

S2. Product Analysis,

S3. Simulated Post-Weld Heat Treatment of Mechanical Test Coupons,

S5. Charpy V-Notch Impact Test,

S6. Drop Weight Test (for Material 0.625 in. [16 mm] and Over in Thickness),

S7. High-Temperature Tension Test,S8. Ultrasonic Examination in Accordance With Specifica-tion A 435 /A 435M,

S9. Magnetic Particle Examination,

S11. Ultrasonic Examination in Accordance With Specification A 577 /A 577M,

S12. Ultrasonic Examination in Accordance With Specification A 578 /A 578M, and

S17. Vacuum Carbon-Deoxidized Steel.